Do you have a broken plastic item that you’d like to fix? Well, you’re in luck! Today, we’re diving into the world of adhesive wonders to answer the burning question: Does Jb Weld work on plastic?

If you’re unfamiliar with Jb Weld, don’t fret – it’s a renowned brand trusted by many DIY enthusiasts and professionals alike. But when it comes to fixing plastic, not all adhesives are created equal. So, let’s find out if Jb Weld is up to the task!

Whether it’s a cracked toy, a shattered phone case, or a broken household item, we’ll explore the effectiveness of Jb Weld in mending plastic items.

Does Jb Weld Work on Plastic?

J-B Weld is a versatile adhesive known for its strength and durability. If you’re wondering if it works on plastic, the answer is yes! J-B Weld is formulated to bond and repair plastic surfaces effectively.

Whether it’s repairing a cracked plastic item or creating a strong bond between plastic parts, J-B Weld is up to the task. Its specialized formula ensures a reliable and long-lasting bond on various types of plastic.

So, rest assured, J-B Weld is the go-to solution for your plastic repair needs!

Science Behind Jb Weld

Jb Weld is a two-part epoxy adhesive that consists of a resin and a hardener. When these two components are mixed together, a chemical reaction occurs, resulting in a strong bond.

This makes Jb Weld a popular choice for repairing a wide range of materials, including metal, wood, and, of course, plastic. The adhesive is known for its high strength, durability, and ability to withstand various environmental conditions.

When applied to plastic, Jb Weld works by creating a strong bond between the broken pieces. The adhesive seeps into the cracks and creates a solid connection, effectively “welding” the plastic back together.

However, it’s important to note that the success of the repair relies heavily on proper surface preparation and application techniques. Let’s explore the factors that can affect the effectiveness of Jb Weld on plastic.

Surface Preparation

One key factor in achieving a successful repair with Jb Weld on plastic is proper surface preparation. Before applying the adhesive, it is crucial to clean the broken plastic surface thoroughly.

Remove any dirt, grease, or residue that may hinder the adhesion process. You can use a mild detergent and water to clean the surface, followed by a rinse and thorough drying. Additionally, roughening the surface with sandpaper can enhance the bond between the Jb Weld and the plastic material.

It’s also important to ensure that the plastic is in a stable condition. If the plastic is deteriorated, brittle, or too damaged, Jb Weld may not be able to provide a reliable and lasting repair. In such cases, it may be necessary to consider alternative repair options or seek professional assistance.

Once the surface is properly prepared, you can proceed with the application of Jb Weld. Follow the instructions provided by the manufacturer, including the recommended mixing ratio of the resin and hardener, as well as the curing time. Applying the adhesive evenly and in the right amount is crucial to ensure a strong and long-lasting bond.

Factors Affecting Bond Strength

While Jb Weld is generally effective in bonding plastic, certain factors can impact the strength of the bond. One such factor is the type of plastic being repaired.

Jb Weld works best on rigid plastics such as ABS, PVC, and acrylic. Softer plastics like polyethylene and polypropylene may not bond as effectively with Jb Weld. It’s always a good idea to consult the manufacturer’s website or contact their customer support for specific recommendations regarding plastic compatibility.

Environmental conditions can also affect the bond strength of Jb Weld on plastic. Extreme temperatures, exposure to chemicals or solvents, and constant moisture can weaken the adhesive over time.

Therefore, it’s important to consider the intended use and environment of the repaired item. If the repaired plastic item is exposed to harsh conditions, it may be necessary to reinforce the bond with additional measures, such as mechanical fasteners or sealing compounds.

In conclusion, Jb Weld can work on plastic, but the success of the repair largely depends on proper surface preparation, the type of plastic being repaired, and environmental factors.

By following the recommended techniques and considering these factors, you can increase the likelihood of a strong and durable bond. Remember to always read and follow the instructions provided by the manufacturer for the best results.

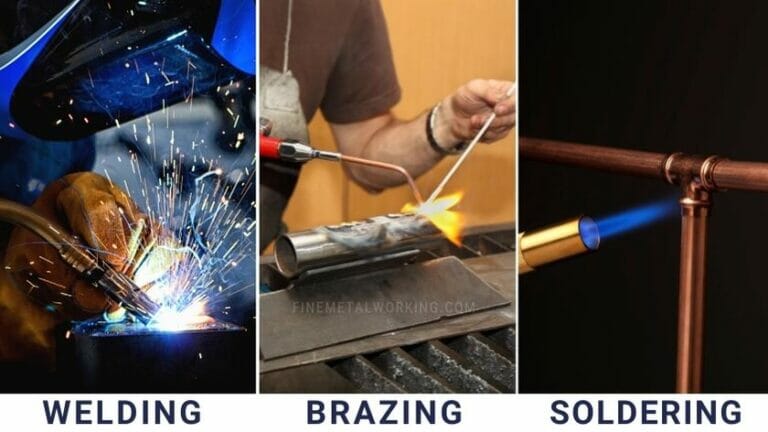

Jb Weld vs. Other Plastic Adhesives

When it comes to choosing an adhesive for plastic repairs, Jb Weld is just one option among many. In this section, we will compare Jb Weld with other popular plastic adhesives to help you make an informed decision.

Cyanoacrylate (Super Glue)

- Cyanoacrylate, commonly known as super glue, is a fast-acting adhesive that can bond plastic surfaces quickly.

- It forms a strong bond, but it may not be as durable or flexible as Jb Weld.

- Super glue is best suited for small repairs and bonding rigid plastics.

- However, it may not work well on certain types of plastic, such as polyethylene and polypropylene.

Epoxy Resin

- Epoxy resin, like Jb Weld, is a two-part adhesive that requires mixing before application.

- It is known for its strength and durability, making it suitable for various types of plastic repairs.

- Epoxy resin can be used on both rigid and flexible plastics.

- However, it may require longer curing times compared to Jb Weld.

Polyurethane Adhesive

- Polyurethane adhesive is a versatile adhesive that can bond a wide range of materials, including plastic.

- It provides a flexible bond and can withstand vibrations and impact.

- However, polyurethane adhesive may not be as strong as Jb Weld in terms of sheer strength.

- It is best suited for applications where flexibility and impact resistance are important.

Ultimately, the choice between Jb Weld and other plastic adhesives would depend on the specific requirements of your repair project.

Consider factors such as the type of plastic, desired bond strength, flexibility, and environmental conditions. It’s always a good idea to consult the manufacturer’s recommendations and conduct a small test before committing to a full repair.

Tips for Using Jb Weld on Plastic

To ensure the best results when using Jb Weld on plastic, consider the following tips:

- Always read and follow the instructions provided by the manufacturer for proper mixing and application techniques.

- Clean the plastic surface thoroughly before applying Jb Weld to ensure maximum adhesion.

- Roughen the surface of the plastic with sandpaper to promote better bond formation.

- Consider reinforcing the repair with additional measures, such as mechanical fasteners or sealing compounds, for added strength in high-stress areas.

- Allow sufficient curing time as specified by the manufacturer before subjecting the repaired plastic item to stress or use.

- Monitor the repaired item for any signs of weakening or failure over time, especially if it will be exposed to extreme temperatures or harsh environmental conditions.

- If you are unsure about the compatibility of Jb Weld with a specific type of plastic, conduct a small test on a non-visible area before proceeding with the full repair.

By following these tips, you can enhance the effectiveness and durability of Jb Weld on plastic repairs. Remember, proper surface preparation, understanding the limitations of Jb Weld, and considering the specific requirements of your repair project are key to achieving successful results.

Jb Weld can work effectively on plastic repairs. However, the success of the repair depends on various factors, including proper surface preparation, the type of plastic being repaired, and environmental conditions.

By following the recommended techniques and considering these factors, you can increase the likelihood of a strong and durable bond. Always read and follow the instructions provided by the manufacturer for the best results.

Remember to consider alternatives and conduct tests if you’re unsure about the compatibility of Jb Weld with a specific type of plastic. Happy repairing!

Frequently Asked Questions

Welcome to our FAQ section on using JB Weld on plastic! Below, we’ve compiled the most commonly asked questions about using JB Weld on plastic surfaces. Read on to find answers to your burning questions!

1. Can I use JB Weld on all types of plastic?

JB Weld is a versatile adhesive and can be used on many different types of plastic surfaces. However, it’s important to note that some plastics have low surface energy which may make it more challenging for JB Weld to adhere to.

In such cases, it’s recommended to use a plastic-specific epoxy that is designed to bond well with these surfaces. Always check the instructions and product specifications before using JB Weld on plastics.

Additionally, it’s a good idea to clean and prepare the plastic surface before applying JB Weld. Make sure to remove any dirt, grease, or residue that may interfere with the bonding process. Sanding the surface lightly can also help create a rougher texture for better adhesion.

2. How long does it take for JB Weld to dry on plastic?

The drying time of JB Weld on plastic can vary depending on several factors including temperature, thickness of the application, and the type of plastic being used. In general, JB Weld dries to touch within 1-3 hours, but full curing can take up to 24 hours or longer.

It’s important to follow the specific instructions provided by JB Weld for the product you are using. Factors such as humidity and temperature can affect drying and curing times, so it’s best to allow sufficient time for the adhesive to fully cure before subjecting it to any stress or load.

3. Is JB Weld waterproof on plastic?

Yes, once JB Weld is fully cured, it forms a strong and waterproof bond on plastic surfaces. This makes it suitable for various applications where water resistance is important, such as repairing plumbing fixtures, automotive parts, or outdoor equipment.

However, it’s important to note that proper surface preparation and application are crucial for achieving a durable and watertight bond. Ensure that the plastic surface is clean, dry, and free from any contaminants that may compromise the adhesion. Following the recommended curing time is also essential to ensure maximum waterproofing.

4. Can JB Weld be sanded and painted on plastic?

Yes, once JB Weld has fully cured, it can be sanded and painted on plastic surfaces. After the adhesive has dried and cured according to the instructions, you can use sandpaper or a sanding block to smooth out any rough edges or uneven surfaces.

Be sure to use fine-grit sandpaper and work gently to avoid damaging the plastic.

After sanding, you can paint the plastic surface using appropriate paints that are compatible with plastics. Make sure to choose paints specifically designed for plastic applications and follow the manufacturer’s instructions for best results. This allows you to achieve a finished look and further protect the repaired or bonded plastic.

5. Can JB Weld withstand heat on plastic?

JB Weld is not designed to withstand high temperatures on plastic surfaces. While it can withstand normal operating temperatures in many applications, it is not recommended for use in situations where extreme heat is present, such as near engines or heating elements.

For applications where heat resistance is crucial, it’s recommended to use adhesives or epoxy specifically formulated for high-temperature environments.

These specialized products are designed to withstand the heat without compromising the bond or structural integrity of the plastic.