When it comes to achieving precision in welding, Pacific Arc TIG Welding is the way to go! With its advanced technology and exceptional performance, Pacific Arc can help you achieve immaculate welds with utmost accuracy. Whether you’re a professional welder or a DIY enthusiast, Pacific Arc TIG Welding will take your welding projects to the next level. Let’s dive in and explore how this incredible welding technique can help you achieve precision like never before.

Precision is the key to successful welding, and Pacific Arc TIG Welding offers unparalleled precision in every weld. By using a Tungsten Inert Gas (TIG) welding process, this technique ensures that you have complete control over the heat input and the filler material, resulting in precise and flawless welds. From intricate metal artwork to critical structural joints, Pacific Arc TIG Welding delivers exceptional accuracy, every time.

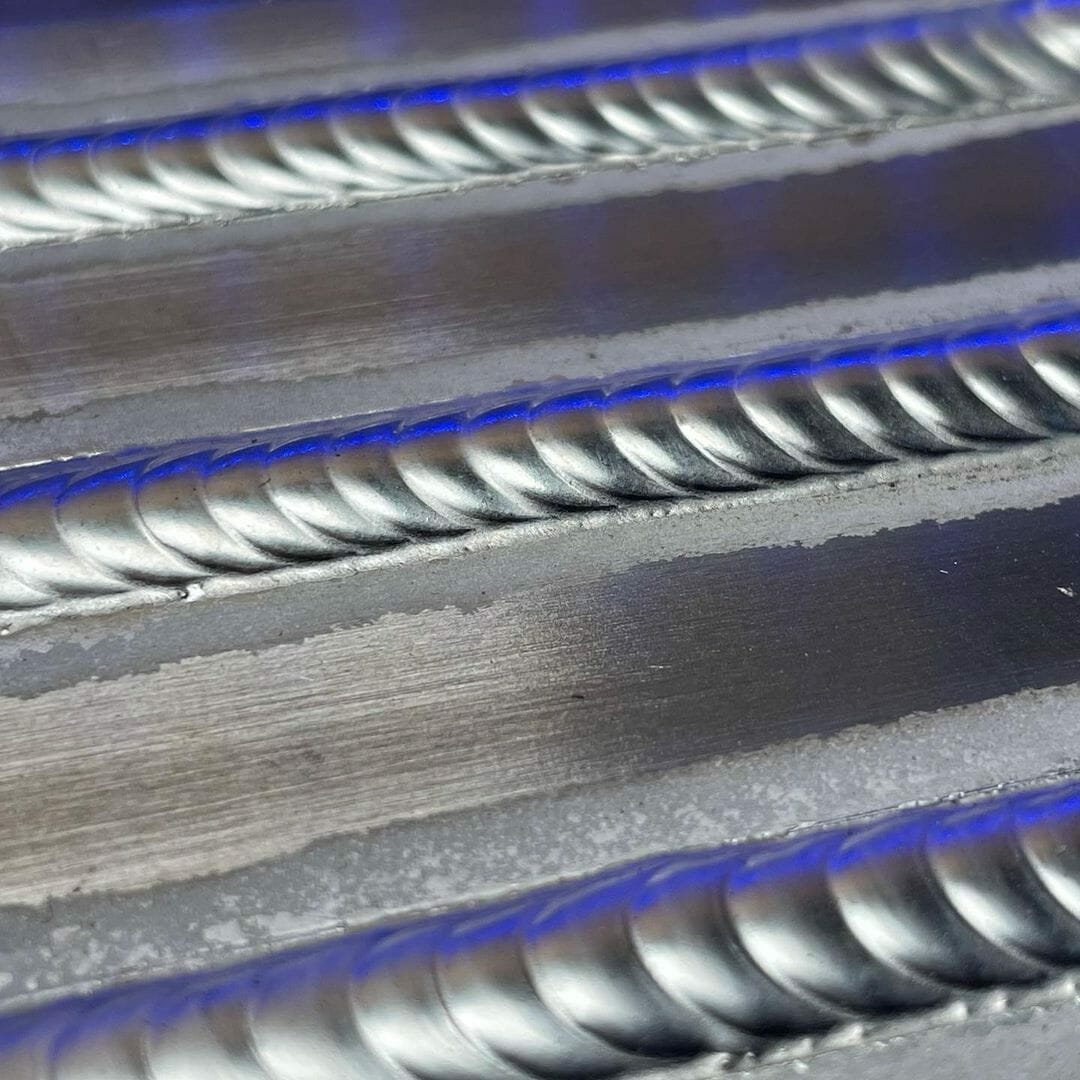

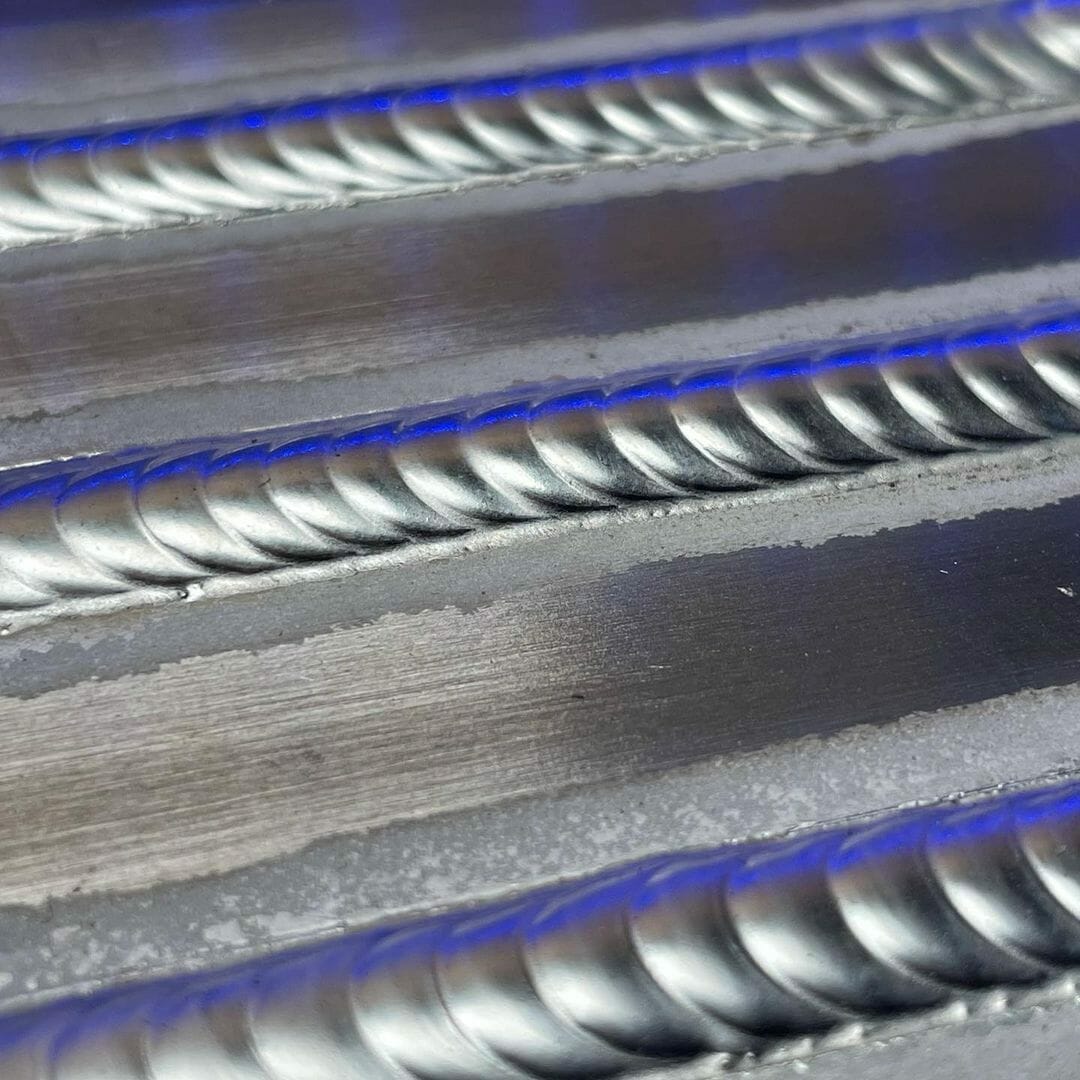

One of the standout features of Pacific Arc TIG Welding is its ability to create clean and aesthetically pleasing welds. The process allows for precise control over the arc length, resulting in minimal spatter and weld splatter. The end result is a visually appealing weld that not only meets the highest standards of quality but also enhances the overall appearance of your project. Whether you’re working on stainless steel, aluminum, or other metals, Pacific Arc TIG Welding will leave you with welds that are both strong and beautiful.

So, if you’re looking to take your welding skills to the next level and achieve precision like never before, Pacific Arc TIG Welding is the answer. Its advanced technology, exceptional performance, and ability to deliver precise and aesthetically pleasing welds make it the go-to choice for professionals and hobbyists alike. Get ready to embark on a welding journey filled with accuracy and perfection with Pacific Arc TIG Welding!

Achieving Precision With Pacific Arc TIG Welding

TIG welding is a popular welding technique known for its precision and versatility. When it comes to achieving the highest level of precision in TIG welding, Pacific Arc is a brand that stands out. With their advanced technology and innovative features, Pacific Arc TIG welders offer welders the ability to create intricate welds with utmost accuracy. In this article, we will delve into the world of Pacific Arc TIG welding and explore the various ways in which it enables welders to achieve unmatched precision.

The Advantages of Pacific Arc TIG Welding

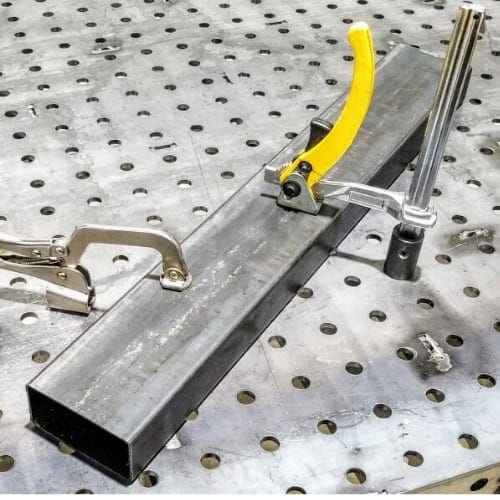

Pacific Arc TIG welding equipment offers a range of advantages that make it the top choice for welders seeking precision. One of the key features of Pacific Arc TIG welders is their advanced arc control. With precise control over settings such as arc length, amperage, and gas flow, welders can achieve consistent and precise welds. This level of control is essential when working on delicate and intricate projects.

Another advantage of Pacific Arc TIG welding is its ability to weld a range of materials. Whether it’s stainless steel, aluminum, or exotic metals, Pacific Arc TIG welders are equipped to handle the job. This versatility allows welders to work on a wide variety of projects without compromising on precision.

Furthermore, Pacific Arc TIG welders are known for their durability and reliability. The robust construction and high-quality components ensure that the welders can withstand the demands of challenging welding environments. This reliability translates to consistent performance, enabling welders to achieve the same high level of precision with each weld.

The Precision of Pacific Arc TIG Welding Machines

Pacific Arc TIG welding machines are designed with precision in mind. One of the key aspects that contribute to their accuracy is the advanced control panel. The intuitive interface allows welders to easily adjust parameters and monitor their settings, ensuring precise control over the welding process.

Additionally, Pacific Arc TIG welders are equipped with features like pulse welding and high frequency stabilization. Pulse welding allows for better heat control, minimizing distortion and ensuring precise bead placement. High frequency stabilization ensures a stable arc, preventing arc wandering and enabling precise welds even on thin materials.

Moreover, Pacific Arc TIG welders utilize advanced inverter technology, which provides a stable and consistent welding current. This technology eliminates fluctuations in amperage, ensuring uniform heat input and resulting in precise and aesthetically pleasing welds.

The Importance of Proper Technique in Achieving Precision

While Pacific Arc TIG welders provide the necessary tools for precision welding, it is crucial for welders to employ proper technique to achieve the desired results. One of the key aspects of achieving precision in TIG welding is maintaining a steady hand. Welders must have a firm grip on the torch and maintain a steady and controlled movement throughout the weld.

Another important factor is proper torch positioning. Maintaining the correct angle and distance between the torch and the workpiece is essential for achieving precise welds. Welders should also ensure that the filler rod is held at the proper angle and introduced at the right rate to achieve consistent and uniform welds.

Furthermore, welders should pay attention to cleanliness and preparation. Proper cleaning of the workpiece, including removing any contaminants or oxides, is crucial for achieving quality welds. Additionally, welders should carefully prepare the joint, ensuring proper fit-up, alignment, and sufficient penetration for a strong and precise weld.

The Benefits of Precision TIG Welding with Pacific Arc

Using Pacific Arc TIG welding equipment to achieve precision offers several benefits. Firstly, precise welds ensure structural integrity, minimizing the risk of weld failure. This is particularly important in industries such as aerospace and automotive where high-quality welds are crucial for safety.

Secondly, precision welding enhances the aesthetic appeal of the finished weld. Clean, precise welds contribute to a professional and polished appearance, which is especially important in industries such as architecture and artistry.

Finally, achieving precision in TIG welding increases overall efficiency. By minimizing rework and producing accurate welds in less time, welders can complete projects more efficiently, saving both time and resources.

Proper Maintenance and Care for Pacific Arc TIG Welding Equipment

To ensure that Pacific Arc TIG welding equipment continues to deliver precision and performance, proper maintenance and care are essential. Regular cleaning of the torch and consumables helps maintain optimal performance and extends the lifespan of the equipment. Additionally, conducting routine inspections and addressing any issues promptly can prevent small problems from escalating into more significant ones.

Furthermore, following the manufacturer’s guidelines for operating parameters and maintenance procedures is essential. Pacific Arc provides detailed instructions and recommendations to ensure that welders get the most out of their equipment and maintain its performance over time.

Lastly, storing the equipment in a clean and dry environment, away from extreme temperatures and moisture, helps protect the delicate internal components and prolongs the lifespan of the equipment.

Taking Precision to the Next Level: Advanced Techniques and Tips

While Pacific Arc TIG welding equipment is designed to facilitate precision, there are additional techniques and tips that welders can employ to take their precision welding skills to the next level.

Honing Your Hand-eye Coordination

Developing good hand-eye coordination is essential for achieving precision in TIG welding. Practice exercises that improve your dexterity and control, such as tracing lines or welding on scraps with intricate patterns. Regular practice will enhance your ability to manipulate the torch precisely and produce consistent welds.

Utilizing Back Purging for Critical Welds

Back purging involves introducing inert gas into the backside of a weld joint to prevent oxidation and ensure the internal portion of the weld is clean and defect-free. This technique is especially important when welding materials that are susceptible to oxidation, such as stainless steel or titanium. By taking the extra step to back purge, welders can ensure the highest level of precision and quality in critical welds.

Using Heat Sinks for Heat Management

Heat sinks are devices that absorb and dissipate heat from the weld area, helping to manage heat buildup and prevent distortion. Using heat sinks strategically can aid in achieving precision by controlling heat input and minimizing the risk of warping or overheating the workpiece.

Conclusion

Achieving precision in TIG welding is a combination of using the right equipment and employing proper techniques. Pacific Arc TIG welding machines provide the necessary tools to achieve unmatched precision, from their advanced control panels to their innovative features. By combining the benefits of Pacific Arc TIG welding with proper technique, welders can produce precise, durable, and aesthetically pleasing welds. Regular maintenance and care of the equipment ensure its longevity and continued performance. By honing their skills and utilizing advanced techniques, welders can take their precision welding to the next level. So, whether you’re working on critical joints or aiming for flawless aesthetics, Pacific Arc TIG welding is the key to achieving precision in your welds.

“`

Achieving Precision With Pacific Arc TIG Welding – Key Takeaways

- Pacific Arc TIG welding offers precise and high-quality welds.

- Using Pacific Arc TIG welding, skilled welders can create intricate and detailed welds.

- Pacific Arc TIG welding allows for better control over heat input and ensures minimal distortion.

- The use of a foot pedal enables welders to adjust amperage and maintain precise control over the welding process.

- Proper training and practice are essential for achieving precision with Pacific Arc TIG welding.

Frequently Asked Questions

When it comes to achieving precision with Pacific Arc TIG welding, there may be some common questions that arise. Below, we’ve answered 5 of these questions to help you gain a better understanding of this welding process.

What is Pacific Arc TIG welding and how does it differ from other welding methods?

Pacific Arc TIG welding is a welding technique that uses a tungsten electrode to create an arc that melts the base metal and forms a strong weld joint. Unlike other welding methods, TIG welding does not require filler material, making it a precise and clean welding process. Its control over heat input and the ability to work with various metals sets Pacific Arc TIG welding apart from other methods.

With Pacific Arc TIG welding, the operator has a high level of control over the arc, allowing for precise welds with minimal distortion. This precision is achieved by using a foot pedal to regulate the amperage, controlling the heat input and welding speed. The ability to make fine adjustments during the welding process gives Pacific Arc TIG welding its reputation for achieving precision welds.

What are the benefits of using Pacific Arc TIG welding?

Pacific Arc TIG welding offers several benefits that make it a preferred choice for precision welds. The ability to weld a wide variety of metals, including aluminum, stainless steel, and copper, is a major advantage. This versatility allows for a range of applications, from automotive to aerospace.

Another benefit of Pacific Arc TIG welding is the clean and precise welds it produces. Due to the absence of filler material, there is minimal spatter and post-weld cleanup required. Additionally, the controlled heat input and the ability to weld thin materials without distortion make it ideal for intricate projects that require high precision.

What safety precautions should I take when using Pacific Arc TIG welding?

When using Pacific Arc TIG welding, it is crucial to prioritize safety. Always wear suitable protective gear, including a welding helmet with proper eye protection and gloves that are heat-resistant. Ensure the work area is well-ventilated to avoid inhaling harmful fumes and gases.

It is also important to have a fire extinguisher nearby and to keep flammable materials away from the welding area. Make sure you are trained in using the specific equipment and understand the proper procedures for setting up and operating the welding machine. Following these safety precautions will help prevent accidents and ensure a safe working environment.

What are some tips for achieving precise welds with Pacific Arc TIG welding?

To achieve precise welds with Pacific Arc TIG welding, it is essential to start with clean and properly prepared materials. Remove any dirt, rust, or contaminants from the surfaces to be welded.

Controlling the heat input is crucial for achieving precision. Use the foot pedal to adjust the amperage and maintain a steady welding speed. It’s also important to practice proper technique and maintain a consistent arc length. Additionally, using the right tungsten electrode and selecting the appropriate shielding gas for the metal being welded can further enhance precision.

Can Pacific Arc TIG welding be used for both thick and thin materials?

Yes, Pacific Arc TIG welding can be used for both thick and thin materials. For thicker materials, a higher amperage setting may be required to generate enough heat for proper fusion. In contrast, when welding thin materials, it is crucial to maintain a low amperage to prevent burn-through or excessive distortion.

The ability to control heat input and adjust welding parameters allows for versatility in working with various thicknesses of metal. With proper technique and parameter settings, Pacific Arc TIG welding can produce precise welds on a wide range of material thicknesses.

Summary

TIG welding with Pacific Arc can help make your welding more precise. It uses a special torch to create a controlled electrical arc, which melts the metal and creates a strong, high-quality weld. Pacific Arc TIG welding is great for thin metals like aluminum, stainless steel, and copper. It’s also versatile and can be used for various projects, from automotive repairs to artistic creations. With TIG welding, you can achieve clean, precise welds that are less likely to have defects or require rework. Just remember to take your time, practice, and follow safety precautions!

In conclusion, using Pacific Arc TIG welding can improve the quality and precision of your welds. It’s a versatile method suitable for various metals and projects. With some practice and safety measures, you’ll be able to create strong, clean welds that will make your projects shine! So grab your torch, put on your safety gear, and get welding with Pacific Arc TIG!