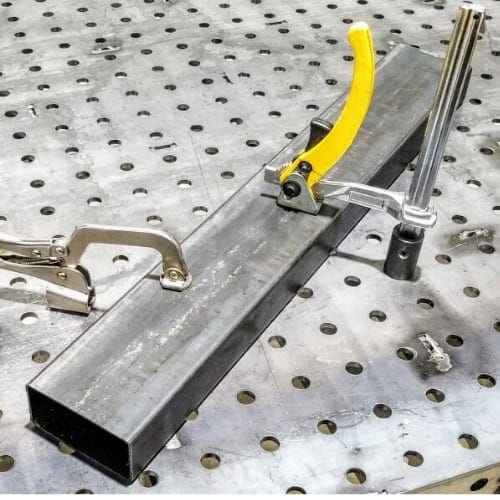

How do welding table clamps work? If you’ve ever been curious about the inner workings of these handy tools, you’re in the right place! Welding table clamps are essential for securing your workpiece in place during welding projects. In this article, we’ll dive into the nitty-gritty details and explain the magic behind welding table clamps.

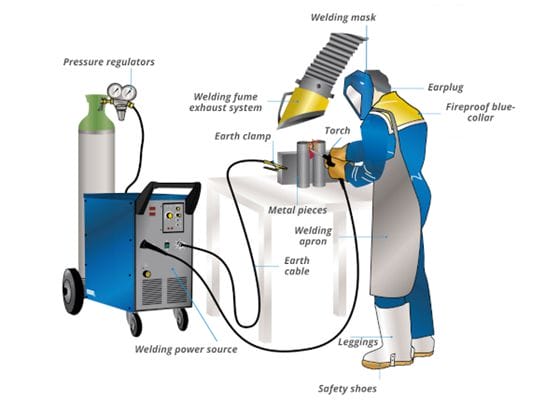

First things first, let’s talk about why you need welding table clamps in the first place. Welding involves joining two pieces of metal together using extreme heat, and it requires precision and stability. Here’s where welding table clamps come in—they grip your workpiece firmly onto the welding table, ensuring it stays put while you work your magic with the welding torch.

Now, you might be wondering, “How do these clamps work?” Well, it’s pretty simple. Welding table clamps typically consist of two main components: the clamp body and the threaded screw.

The clamp body is designed to hold the workpiece securely, while the threaded screw allows you to tighten or loosen the clamp as needed. With just a few turns of the screw, you can firmly secure your workpiece in place, providing stability and allowing for precise welding. Pretty cool, right?

So, in a nutshell, welding table clamps are the unsung heroes of welding. They keep your workpiece steady and secure, ensuring your welding projects turn out just the way you want them to.

Now that we’ve scratched the surface, let’s explore the world of welding table clamps in more detail. Get ready to discover tips, tricks, and everything you need to know about these versatile tools.

How Do Welding Table Clamps Work?

Here are some simple steps which you need to follow if you want to do the work properly.

- Choose the right clamp size for your welding table.

- Align the clamp’s base with the workpiece.

- Tighten the clamp’s handle to secure the workpiece firmly.

- Ensure the clamp is perpendicular to the table for stability.

- Release the clamp by loosening the handle when finished.

Welding table clamps are essential tools that provide stability and precision during welding projects. By following these steps, you can effectively use welding table clamps for your welding needs.

1. Types of Welding Table Clamps

There are various types of welding table clamps available, each designed for specific applications. Some common types include:

- C-Clamps: These clamps have a C-shaped frame with a screw mechanism for tightening. They can be used for a wide range of welding projects and provide a strong grip on flat surfaces.

- F-Clamps: F-clamps have an F-shaped bar and a sliding jaw for quick adjustment. They are versatile and can be used on both flat and irregular-shaped workpieces.

- Grip Pliers: These clamps, also known as locking pliers, have a unique mechanism that allows them to lock securely onto a workpiece. They are ideal for holding small or irregular-shaped objects.

- Toggle Clamps: Toggle clamps are operated by a lever mechanism and provide quick and secure clamping. They are commonly used in assembly and welding jigs.

These are just a few examples of welding table clamps available in the market. Each type has its own unique features and advantages, allowing welders to choose the best clamp for their specific needs.

Working Principle of Welding Table Clamps

The working principle of welding table clamps is relatively simple. The clamps utilize a combination of mechanical force and grip to hold the workpiece firmly in place. Here’s how they work:

When a welding table clamp is tightened, the screw mechanism or sliding jaw applies pressure to the workpiece. The force exerted creates a secure grip, preventing any movement or slippage during welding. The clamps are designed to distribute the force evenly across the workpiece’s surface, minimizing the risk of deformation or damage.

Additionally, welding table clamps often have specially designed jaws or pads to enhance grip and minimize surface marring. These features allow for a more precise and controlled welding process, ensuring accurate alignment and joint integrity.

Benefits of Using Welding Table Clamps

Using welding table clamps offers several benefits that contribute to the overall quality and efficiency of the welding process. Here are some key advantages:

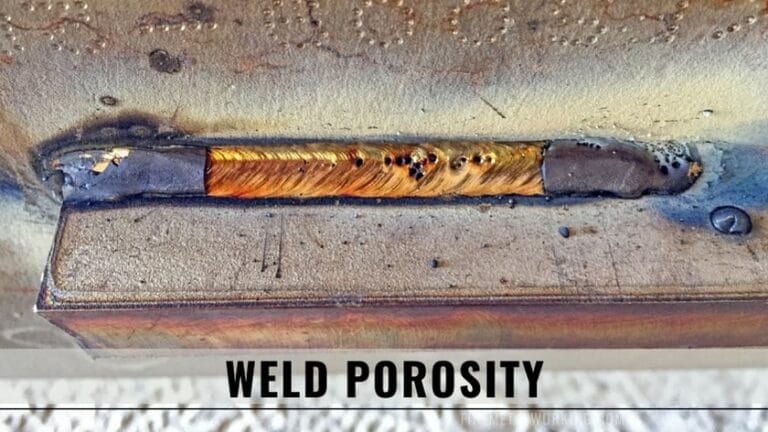

- Secure Workpieces: Welding table clamps provide a secure hold on workpieces, preventing movement and slippage. This stability allows for precise and accurate welding, resulting in high-quality welds with minimal defects.

- Increased Safety: Clamping workpieces reduce the risk of accidents and injuries during welding. It ensures that the workpiece remains in a fixed position, reducing the chance of it coming into contact with the welder’s hands or body.

- Enhanced Efficiency: By holding the workpiece securely, welding table clamps free up the welder’s hands, enabling them to focus on the welding process itself. This improves productivity and allows for smoother workflow.

- Versatility: Different types of welding table clamps allow for the secure clamping of various workpiece shapes and sizes. They can be used in a wide range of welding applications, making them versatile tools in any metalworking shop.

Welders need to have a good understanding of how welding table clamps work and how to use them effectively. By selecting the right type of clamp and employing proper clamping techniques, welders can ensure the success of their welding projects and achieve superior results.

Factors to Consider When Choosing Welding Table Clamps

When choosing welding table clamps, there are several important factors to consider. Here are three key considerations:

1. Material and Strength

Welding table clamps are subjected to significant forces during the welding process. It is crucial to select clamps that are made from durable materials such as steel or cast iron, ensuring they can withstand the pressure. Additionally, consider the clamps’ strength rating and choose ones that match the requirements of your welding projects.

2. Grip Range and Adjustment

Depending on the size and shape of the workpiece, the clamps’ grip range and adjustment capabilities are essential. Look for clamps that can accommodate a wide range of workpiece sizes and offer quick and easy adjustment mechanisms, such as sliding jaws or threaded screws.

3. Special Features and Accessories

Some welding table clamps come with special features or accessories that can enhance their functionality. For example, swivel pads can provide a better grip on irregular-shaped workpieces, and quick-release mechanisms allow for faster setup and removal. Consider these additional features based on your specific welding needs.

By carefully considering these factors, welders can select the most suitable welding table clamps for their projects, ensuring optimal performance and reliable clamping capabilities.

Frequently Asked Questions

Welding table clamps play a crucial role in ensuring stability and precision during welding projects. These clamps are designed to securely hold workpieces in place, allowing welders to work efficiently and produce high-quality welds. Here are some common questions about how welding table clamps work:

1. How do welding table clamps hold the workpiece in place?

Welding table clamps typically have a strong grip mechanism that allows them to tightly hold the workpiece. They often use a combination of screws, levers, or cam mechanisms to provide a secure and adjustable hold. When tightened, the clamps apply pressure on the workpiece, preventing it from shifting or moving during the welding process.

Some clamps also have swivel or adjustable features that allow them to adapt to different shapes and sizes of workpieces. This versatility is essential for accommodating various welding projects and ensuring a stable grip on the workpiece.

2. Can welding table clamps be used on different types of welding tables?

Yes, welding table clamps can be used on different types of welding tables as long as they are compatible. Most welding table clamps are designed with universal mounting options, allowing them to be used on different surfaces. Whether you have a steel, aluminum, or cast iron welding table, there are clamps available that can securely attach to the table.

It is important to consider the size, weight capacity, and compatibility of the clamps with your specific welding table. Some clamps may require additional hardware or adapters to ensure a proper fit. Always check the manufacturer’s guidelines to ensure you are using the correct clamps for your welding table.

3. Do welding table clamps leave marks or damage on the workpiece?

Welding table clamps are designed to minimize marks or damage on the workpiece, but it depends on the clamps and the material being welded. Clamps with protective pads or non-marring surfaces can help prevent scratches or marks on the workpiece.

However, it is still essential to use caution and take appropriate measures to protect the workpiece. Placing scrap material or heat-resistant pads between the clamp and the workpiece can further safeguard against any potential damage caused by the clamps.

Additionally, using the appropriate amount of pressure and not overtightening the clamps can help prevent distortion or indentations on the workpiece.

4. Are welders able to adjust the clamps during the welding process?

Yes, welders can adjust welding table clamps during the welding process to maintain optimal positioning and stability. The ability to make fine adjustments allows for better access to the weld joint and ensures the workpiece remains securely in place.

Some clamps have quick-release mechanisms or feature handles and knobs that make it easier to loosen or tighten the clamps without interrupting the welding process. Adjustments may be necessary when working on long welds or when repositioning the workpiece for different welding angles.

5. Can welding table clamps be used in conjunction with other welding tools?

Absolutely! Welding table clamps can be used in conjunction with other welding tools to enhance efficiency and accuracy. They can work hand-in-hand with welding fixtures, magnetic clamps, or angle clamps to provide additional support and positioning options.

By combining different tools, welders can create customized setups that cater to their specific welding needs. These tool combinations allow for increased stability, precise alignment, and improved workflow, resulting in better welding results.

Welding table clamps are handy tools that hold pieces of metal together during welding. They work by tightening a screw, which applies pressure and keeps the metal steady.

These clamps have a wide range of uses and can be adjusted to fit different sizes of metal. They help to ensure precise and secure welding, making the process safer and more efficient.

In conclusion, welding table clamps are essential for any welding project, providing stability and accuracy. They are easy to use and play a crucial role in creating strong and durable welds. So, if you’re planning to take up welding, make sure to get your hands on some reliable welding table clamps!