Are you ready to dive into the world of woodworking? Whether you’re a seasoned pro or just starting out, choosing the right tools is crucial. And when it comes to tackling hardwood projects, finding the perfect circular saw is essential.

But with so many options out there, how do you know which one is right for you? Don’t worry, we’ve got you covered! In this guide, we’ll walk you through the ins and outs of selecting the best circular saw for hardwood. Let’s get cutting!

When it comes to hardwood, you need a circular saw that can handle the tough stuff. But with a wide variety of models, features, and price points on the market, it can be overwhelming to make a decision. That’s where we come in!

We’re here to simplify the process and help you find the perfect tool for your woodworking needs.

From cutting power to blade size, we’ll break down the important factors to consider when choosing a circular saw for hardwood projects. So let’s roll up our sleeves and find the saw that will have you making precise and clean cuts in no time!

How to Choose the Right Circular Saw for Hardwood?

Follow these steps to choose the best circular saw for hardwood projects,

- Determine the Type of Cut Needed: Consider whether you need a crosscut, rip cut, or bevel cut.

- Assess Power and Speed: Look for a saw with sufficient power and a high RPM rating to handle hardwood.

- Check Blade Size and Tooth Count: Larger blades with more teeth are ideal for hardwood.

- Consider Bevel Capacity and Adjustability: Make sure the saw can make precise bevel cuts.

- Ergonomics and Safety Features: Look for a comfortable grip and safety features like blade guards.

1. Power: Ensuring Sufficient Cutting Strength

The power of a circular saw determines its cutting efficiency and the range of materials it can handle. When it comes to hardwood, you’ll need a saw with ample power to effortlessly slice through dense and tough wood fibers.

Opt for a circular saw with a high amp rating, typically ranging between 10 and 15 amps, to ensure the necessary cutting strength. This power rating allows the saw to efficiently cut through hardwood without bogging down or overheating.

In addition to considering the amp rating, pay attention to the saw’s motor type. Brushless motors are known for their enhanced performance, durability, and extended lifespan. They provide more power while also being lighter and more compact compared to their brushed counterparts.

Finally, selecting a circular saw with a corded or cordless design comes down to personal preference. Corded saws are generally more powerful, offering consistent performance throughout the cutting process.

On the other hand, cordless saws bring flexibility and portability, allowing you to work freely without worrying about a power source.

2. Blade Type

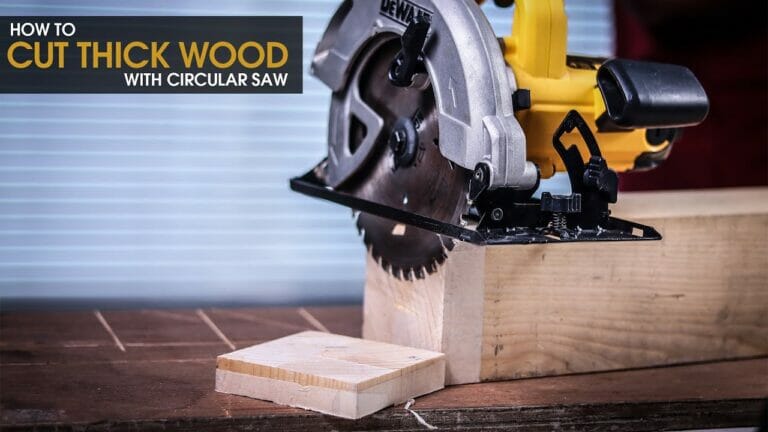

The type of blade you use in your circular saw plays a crucial role in achieving clean and precise cuts in hardwood. The two main factors to consider when selecting a blade are its diameter and tooth configuration.

For hardwood, a larger blade diameter is recommended to ensure deeper cuts. Look for blades with diameters between 7.25 and 8.5 inches, as they offer a greater cutting capacity. Additionally, pay attention to the number of teeth on the blade.

More teeth provide smoother cuts, while fewer teeth produce faster cuts. For hardwood, a blade with around 40 to 60 teeth strikes a good balance between speed and smoothness.

Furthermore, choosing the right tooth configuration is vital. For crosscuts and ripping in hardwood, opt for a blade with alternate top bevel (ATB) teeth. This tooth design reduces splintering and tear-out, resulting in cleaner cuts.

Fine-tooth blades with high tooth counts also work well for precision cutting, such as when making intricate shapes or joints in hardwood.

3. Cutting Capacity

When selecting a circular saw for hardwood, it’s essential to ensure that it can handle the cutting capacity you require. The cutting capacity of a circular saw is determined by its maximum cutting depth and bevel capacity.

For hardwood, a saw with a cutting depth of at least 2-3/8 inches is recommended to accommodate thick boards and make deep cuts. Additionally, consider the bevel capacity of the saw, which allows for angled cuts.

Look for a circular saw with a bevel capacity of 45 degrees or more to have the flexibility for various woodworking projects that involve beveling hardwood edges.

It’s worth mentioning that circular saws with adjustable depth and bevel settings offer increased versatility, allowing you to make precise and custom cuts according to your project requirements.

4. Safety Features

When working with any power tool, safety should always be a top priority. Circular saws designed for hardwood often come with specific safety features that you should look out for.

One crucial safety feature is an electric brake. This feature rapidly stops the blade from spinning within seconds of releasing the trigger, minimizing the risk of accidents or injuries.

Additionally, a blade guard is essential to cover the blade when it is not in use, preventing accidental contact and injuries. Some circular saws also feature an integrated dust blower that keeps the cutting line clear of sawdust for improved visibility.

Furthermore, a sturdy and ergonomic design contributes to safe and comfortable operation. Look for circular saws with a non-slip grip and a well-balanced weight distribution to reduce fatigue during extended periods of use.

Some models also offer built-in LED lights that illuminate the cutting area, ensuring greater precision and reducing the chances of mistakes or accidents.

5. Additional Features

While the core factors mentioned above are crucial in choosing the right circular saw for hardwood, some additional features can further enhance the precision and convenience of your woodworking projects.

An integrated laser guide, for example, projects a beam onto the work surface, allowing for more accurate cutting along a marked line. This feature is particularly handy for beginners or tasks that require extreme precision.

Another beneficial feature is a blower or dust extraction system, which helps keep the work area clean and free from sawdust, improving visibility and reducing the need for cleanup afterward.

Some circular saws also offer advanced features like cutting depth indicators, which allow you to set precise depth measurements for consistent and uniform cuts.

Additionally, some models include built-in scales and rulers on the base plate for quick and easy measurements, eliminating the need for additional tools.

6. Budget

Lastly, while investing in a high-quality circular saw is essential for achieving excellent results, it’s important to set a budget that aligns with your needs and expectations. Circular saws for hardwood are available in a wide price range, from budget-friendly options to professional-grade models.

Consider the nature and frequency of your woodworking projects, and determine the level of performance and durability required. If you’re a hobbyist or occasional user, an entry-level or mid-range circular saw may suffice.

However, professionals or those engaging in heavy-duty woodworking may benefit from investing in a top-of-the-line circular saw with advanced features and robust construction.

Remember, while it’s tempting to opt for the most affordable option, compromising on quality and performance could lead to frustrations and limitations in the long run.

Find the right balance between affordability and functionality to make the most out of your circular saw for hardwood.

Frequently Asked Questions

When it comes to choosing the right circular saw for hardwood, there are a few important factors to consider. Whether you’re a professional woodworker or a DIY enthusiast, finding the right tool can make all the difference in your woodworking projects. Here are some commonly asked questions about selecting the right circular saw for hardwood.

1. What type of circular saw is best for cutting hardwood?

When it comes to cutting hardwood, a worm drive circular saw is often the best choice. Worm drive saws have a gearbox that provides more torque, making them ideal for cutting denser materials like hardwood. They also offer better blade visibility, allowing for more precise cuts.

Another option is a sidewinder (or direct drive) circular saw, which is lighter and more maneuverable. These saws have the motor located alongside the blade, making them easier to handle. However, they may not have the same power as worm drive saws, so consider the type of hardwood you’ll be cutting before making a decision.

2. What size circular saw blade should I use for hardwood?

When working with hardwood, using the right blade size is crucial for achieving clean and precise cuts. For most hardwood cutting applications, a 7-¼ inch circular saw blade is recommended.

This size provides a good balance between cutting capacity and maneuverability.

Make sure to choose a blade specifically designed for hardwood cutting, with carbide teeth that can withstand the hardness of the material.

It’s also important to check the blade’s tooth count – a higher tooth count will result in smoother cuts, while a lower tooth count will cut faster but may be rougher.

3. What features should I look for in a circular saw for hardwood?

When selecting a circular saw for hardwood, there are several features to consider. First, check the saw’s cutting depth and bevel capacity to ensure it can handle the thickness and angle of the hardwood you’ll be working with.

Look for a saw with a sturdy and comfortable grip that allows for precise control.

Additionally, consider the saw’s power source – corded saws provide constant power, but cordless saws offer greater portability. Another useful feature is an adjustable dust blower, which keeps the cutting area clear for improved visibility.

Finally, pay attention to the saw’s weight, as a lighter saw can reduce fatigue during long woodworking sessions.

4. Does the brand of the circular saw matter when cutting hardwood?

While the brand does play a role, it’s not the only factor to consider when choosing a circular saw for hardwood. It’s important to prioritize the saw’s overall quality, performance and features over brand loyalty.

Look for reputable brands known for producing reliable and durable tools, and read reviews to get an idea of their performance specifically for hardwood cutting.

Remember that each brand may have different models with varying features, so it’s worth comparing different options. Ultimately, choose a circular saw that meets your specific needs and budget.

5. How much should I expect to spend on a circular saw for hardwood?

The price range for circular saws can vary greatly depending on the brand, features, and quality. Entry-level circular saws suitable for cutting hardwood can typically be found in the range of $50 to $100. These saws may have basic features but can still get the job done.

For higher-end models with more advanced features and better durability, you may need to spend anywhere from $100 to $300 or more. Consider your budget and the frequency and intensity of your woodworking projects to determine the right balance between price and performance.

Choosing the right circular saw for hardwood is important for getting the job done right. First, consider the power of the saw. More power means easier cutting. Next, look at the blade size. A larger blade can cut through thicker wood.

Also, pay attention to the bevel capacity, which determines the angle at which the saw can cut. Finally, consider the safety features of the saw, such as blade guards and safety switches. By considering these factors, you can choose the perfect circular saw for hardwood projects.

Remember, safety should always come first. Always wear protective gear like goggles and gloves when using a circular saw. Take your time and practice proper cutting techniques.

With the right circular saw and precautions in place, you’ll be able to tackle any hardwood project with confidence.