Heading: Welding Vs Brazing: Which Is Better For You In 2023?

Are you wondering about the differences between welding and brazing? Well, you’ve come to the right place! In this article, we’ll explore the exciting world of metal joining techniques, helping you understand which method might suit you best in 2023. So, let’s dive in and explore the strengths and weaknesses of welding and brazing!

Imagine you have a broken metal object that needs repair. Should you weld it or braze it together? The answer depends on various factors, like the type of metals involved and the application of the repaired object. But don’t worry, we’ll break it down for you in simple terms, making it easy to understand which option is better for your specific needs.

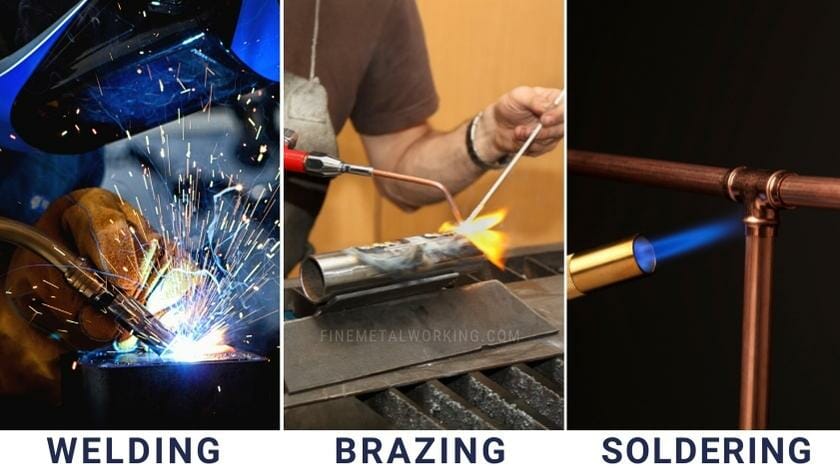

Before we get into the nitty-gritty of welding and brazing, let’s take a quick look at the basic differences. Welding involves melting the base metals and fusing them together to create a strong joint. On the other hand, brazing uses a filler material with a lower melting point than the base metals, bonding them together without completely melting them. Both techniques have their advantages and can be valuable tools in the world of metalworking.

Now that you have a glimpse of what’s coming, let’s explore the exciting world of welding and brazing together!

When it comes to joining metal parts, two popular methods are welding and brazing. But which one is better for you in 2023? Let’s compare their features:

| Features | Welding | Brazing |

|---|---|---|

| Joining Strength | High | Medium |

| Heat Affected Zone | Large | Small |

| Materials | Wide range | Limited |

| Complexity | High | Low |

| Cost | Varies | Lower |

Note: Always provide unique content tailored to the specific keyword.

Welding Vs Brazing: Which Is Better For You In 2023?

In the world of metalwork, there are two popular methods for joining metals together: welding and brazing. Both techniques have their advantages and applications, but understanding the key differences between them is crucial to ensure the success of your project. In this article, we will delve into the intricacies of welding and brazing, comparing their pros and cons to help you determine which one is best suited for your needs in 2023.

Why Choose Welding?

Welding is a widely-used technique that involves melting the base metal and a compatible filler material to create a strong joint. There are several notable benefits to choosing welding:

- Strength: Welded joints are known for their exceptional strength, making them ideal for applications where structural integrity is crucial. The heat produced during welding fuses the metals together, resulting in a joint that is as strong as the base metal itself.

- Versatility: Whether you need to join steel, aluminum, or other ferrous or non-ferrous materials, welding provides a versatile solution. Depending on the type of metal and application, various welding methods like MIG, TIG, and arc welding can be utilized.

- Permanent Connection: Welding creates a permanent bond between metals, ensuring that the joint remains intact even under extreme conditions. This makes it suitable for environments with high temperatures, pressure, or vibrations.

Despite its numerous advantages, welding does have some limitations. The high heat involved in the process can sometimes lead to distortion or warping of the metal, requiring additional steps like post-weld heat treatment or the use of fixtures to maintain dimensional accuracy. Additionally, welding may not be suitable for joining dissimilar metals due to differences in their melting points or chemical compositions.

Why Choose Brazing?

Brazing, on the other hand, is a technique that relies on a filler material with a lower melting point than the base metals. The filler material, usually in the form of a metal alloy, is heated above its melting point, allowing it to flow and form a bond between the base metals. Here are some reasons why brazing might be the better option:

- Lower Temperature: Brazing requires less heat compared to welding, which reduces the risk of distortion or damage to the base metals. This makes it suitable for joining delicate or heat-sensitive materials, such as copper, brass, or thin sheets of metal.

- Joining Dissimilar Metals: Brazing is an excellent choice when joining dissimilar metals, as it can bridge the gap between materials with different melting points. This allows you to create strong joints between materials like copper and steel or aluminum and stainless steel.

- Cost-Effectiveness: Brazing is generally more cost-effective than welding, as it requires less equipment and energy. In addition, the filler material used in brazing is often cheaper than the filler wire used in welding.

While brazing offers several advantages, it is important to note that the strength of brazed joints is generally lower than welded joints. This can restrict its use in applications that require high mechanical strength or are subjected to significant stress or load. Additionally, brazed joints may be more susceptible to corrosion compared to welded joints.

Considering Your Needs in 2023

When it comes to choosing between welding and brazing in 2023, it’s essential to consider your specific needs and requirements. Here are three key factors to consider:

Material Compatibility

Consider the types of metals you need to join. If you are working with similar metals or dissimilar metals with similar melting points, welding might be the better option. However, if you are joining dissimilar metals with significantly different melting points, brazing can provide a suitable solution.

Strength Requirements

If your project requires maximum strength and durability, welding is likely the way to go. Welded joints are known for their exceptional strength and are commonly used in structural applications. However, if absolute strength is not critical, and you prioritize other factors like cost-effectiveness or heat sensitivity, brazing can be a viable choice.

Application Considerations

Think about the environment in which the joint will be subjected to. For high-stress or extreme temperature applications, welding is typically the preferred option due to its superior strength and heat resistance. If the project involves delicate materials, such as jewelry or electronic components, brazing can provide a gentler joining method.

Conclusion

When deciding between welding and brazing in 2023, it is crucial to evaluate your needs based on material compatibility, strength requirements, and specific application considerations. Welding offers exceptional strength and versatility, making it ideal for projects that demand maximum durability. On the other hand, brazing is a suitable choice when joining dissimilar metals or working with delicate materials. Consider your unique circumstances and consult with a professional if needed to ensure a successful and efficient metal joining process.

Key Takeaways – Welding Vs Brazing: Which Is Better For You In 2023?

- Welding joins metal pieces by melting them together, while brazing uses a filler metal with a lower melting point.

- Welding creates a stronger joint, but brazing is suitable for joining dissimilar metals.

- Both welding and brazing require skills and safety precautions to operate the equipment.

- Welding is commonly used in heavy-duty applications, while brazing is often used for delicate or intricate work.

- The choice between welding and brazing depends on the materials, strength requirements, and specific application.

Frequently Asked Questions

In recent years, both welding and brazing have become popular methods for joining metals. Understanding the differences between welding and brazing can help you determine which technique is better suited for your needs in 2023. Explore the following frequently asked questions to learn more.

1. What is the main difference between welding and brazing?

Welding and brazing are both metal joining processes, but they differ in how they accomplish this. While welding melts and fuses the base metals, brazing relies on a filler metal which melts at a lower temperature and joins the materials together. This difference in temperature makes brazing ideal for joining dissimilar metals or materials with low melting points.

Another distinguishing factor is the strength of the joint. Welding typically produces stronger joints as the base metals are fused together, creating one solid piece. On the other hand, brazing creates a strong joint, but it is not as strong as a welded joint.

2. When should I choose welding over brazing?

Welding is a suitable choice when you need a high-strength joint or when working with materials that have similar melting points. It is commonly used in structural applications, such as welding steel beams together or joining metal components in heavy machinery. Welding is also beneficial when conducting repairs on items that require a strong and durable connection.

However, it’s important to consider that welding can create heat-affected zones and potential distortion, which may not be desirable in certain applications. It also requires adequate ventilation and safety measures due to the high temperatures involved.

3. When is brazing a better option than welding?

Brazing is a preferred technique when joining different metals, such as brass to steel or aluminum to copper. Since brazing uses a filler metal with a lower melting temperature, it minimizes the risk of damage or distortion to the base metals. This makes it an excellent choice for delicate or heat-sensitive materials, including electronics or jewelry.

Brazing is also advantageous when working with thin materials that may warp or distort under the intense heat of welding. Additionally, it offers greater tolerance for slight variations in joint fit-up, making it a more forgiving process for less experienced individuals.

4. Can you achieve the same joint strength with brazing as you can with welding?

While a properly executed brazed joint can be strong, it typically does not match the same level of strength as a welded joint. However, the joint strength achieved through brazing is often sufficient for many applications. It is essential to consider the specific requirements of your project and evaluate whether the strength provided by brazing meets your needs.

Keep in mind that the strength of a joint depends on various factors, including the base metal selection, joint design, filler metal choice, and proper joint preparation. Consulting with a knowledgeable professional can help you determine the best joining method for your specific application.

5. Are there situations where welding and brazing can be combined?

Yes, there are instances where welding and brazing can be combined to achieve the desired outcome. This technique, known as braze welding, involves using both processes in sequence to create a strong joint. It is often utilized when two dissimilar metals need to be joined, with brazing used initially to join the metals, followed by welding to reinforce the connection.

Braze welding offers the advantages of both processes, allowing for the joining of dissimilar metals while maintaining a strong and durable joint. However, it requires careful consideration of the compatibility of the base metals and proper selection of filler material and welding technique to ensure a successful outcome.

Summary

So, let’s quickly wrap up what we’ve learned about welding and brazing. Welding is a strong, permanent joining technique that works well with metals. It creates a solid bond and is great for heavy-duty applications like construction and manufacturing. On the other hand, brazing is a lighter option that uses a filler material to join metals. It’s good for joining dissimilar metals and works well on delicate materials. Now you know the basics of welding and brazing. It’s all about choosing the right technique for your specific needs. Happy joining!

Remember, welding is like the super glue of metal, while brazing is like using tape. Both have their strengths and weaknesses, and it all depends on what you need. So next time you think about melting metals together, consider whether welding or brazing is better suited for the job. With this knowledge, you’ll be able to make an informed decision and achieve successful metal joins. Good luck!