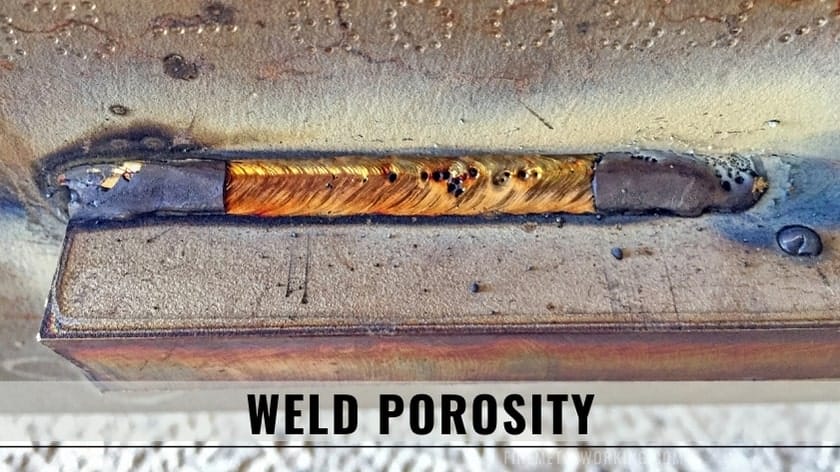

What Causes Porosity in Welding? Well, have you ever wondered why welds can sometimes have tiny holes or bubbles in them? These imperfections are known as porosity, and they can weaken the weld and make it less durable. But fear not, because in this article, we’ll dive into the fascinating world of welding and uncover the mysterious causes of porosity.

You see, welding is a process that joins two pieces of metal together using extreme heat. But sometimes, during this process, gases like hydrogen and nitrogen can get trapped in the molten metal.

And when the metal cools down and solidifies, these gases are trapped, forming those tiny bubbles we call porosity.

So, what exactly causes these gases to get trapped in the molten metal? Well, it can be due to a variety of factors such as improper shielding gas, contaminated welding materials, or even inadequate cleaning of the metal surfaces. But don’t worry, we’ll explore each of these causes in detail and provide you with some handy tips to prevent porosity in your welds.

So, let’s get started and uncover the secrets behind this pesky welding phenomenon!

What Causes Porosity in Welding?

Porosity in welding refers to the presence of small gas pockets or voids in the weld metal. Several factors can cause porosity, such as moisture, contamination, improper shielding gas, or incorrect welding parameters.

Moisture can come from improper storage or handling of electrodes or high humidity in the environment. Contamination can occur from dirty surfaces or the presence of oils, paints, or coatings. Using the correct shielding gas and optimizing welding parameters can help reduce porosity in welding.

Moisture and Contaminants

Moisture and contaminants are one of the primary causes of porosity in welding.

When moisture or contaminants, such as oil, grease, or dirt, are present on the surface of the materials being welded, they can get trapped in the weld pool. As the weld solidifies, these impurities become trapped within the weld, resulting in small cavities or voids known as porosity.

To prevent porosity caused by moisture and contaminants, it is crucial to ensure that the materials being welded are clean and free from any moisture or contaminants.

This can be achieved by properly cleaning and prepping the surfaces before welding, using clean and dry welding consumables, and storing the materials in a clean and dry environment.

Additionally, using proper shielding gases during the welding process can help to prevent porosity. Shielding gases, such as argon or carbon dioxide, create a protective atmosphere around the weld pool, preventing moisture and contaminants from entering and causing porosity.

Inadequate Shielding Gas Coverage

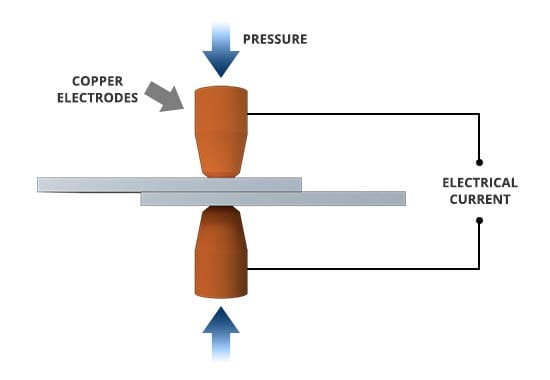

Inadequate shielding gas coverage is another common cause of porosity in welding. When the shielding gas flow rate is insufficient or if there are obstructions that prevent the gas from fully covering the weld pool, the weld can become exposed to the surrounding air. This exposure can lead to the formation of porosity.

To ensure adequate shielding gas coverage, it is essential to use the correct flow rate for the specific welding process and materials being used.

The flow rate should be adjusted according to the weld size and configuration. Additionally, it is important to inspect and maintain the gas nozzles and diffusers to ensure they are free from any obstructions that may impact gas flow.

Regularly monitoring the shielding gas during the welding process is also recommended.

Gas leaks, improper gas supply, or interruptions in gas flow can result in inadequate coverage and an increased risk of porosity. Proper training and knowledge of the welding equipment and processes can help to identify and address issues related to shielding gas coverage.

Improper Welding Technique

Improper welding techniques can contribute to the formation of porosity in welds. Welding too quickly, using excessive heat, or improper arc length can all lead to porosity. These factors can cause the weld pool to become unstable, trapping gases and impurities and resulting in porosity.

To prevent porosity caused by improper welding techniques, it is important to follow proper welding procedures.

This includes selecting the appropriate welding parameters, such as the correct heat input, travel speed, and electrode angle. Adequate preheating and post-weld heat treatment may also be necessary to minimize the risk of porosity and ensure a sound weld.

Regular training, practice, and supervision are essential for welders to develop and maintain proper welding techniques.

Continuously monitoring and adjusting welding parameters during the welding process can help to prevent porosity caused by improper technique.

Gas Contamination

Gas contamination can also contribute to the formation of porosity in welding. Contaminated shielding gases, such as gases containing hydrogen or oxygen, can react with the molten metal and form gas bubbles, leading to porosity.

To prevent gas contamination, it is crucial to use pure and properly stored shielding gases.

Regularly checking gas cylinders for signs of contamination, such as rust or moisture, and properly maintaining gas delivery systems can help to ensure pure gas supply. Welding procedures that involve sensitive materials or critical applications may require additional measures, such as using gas purifiers or analyzers, to ensure gas purity and prevent porosity.

Regular testing and analysis of shielding gases can also help to identify and address potential issues related to gas purity. Collaboration with gas suppliers and experts in gas control and monitoring can provide valuable insights and support in preventing gas contamination and mitigating the risk of porosity.

Metallurgical Issues

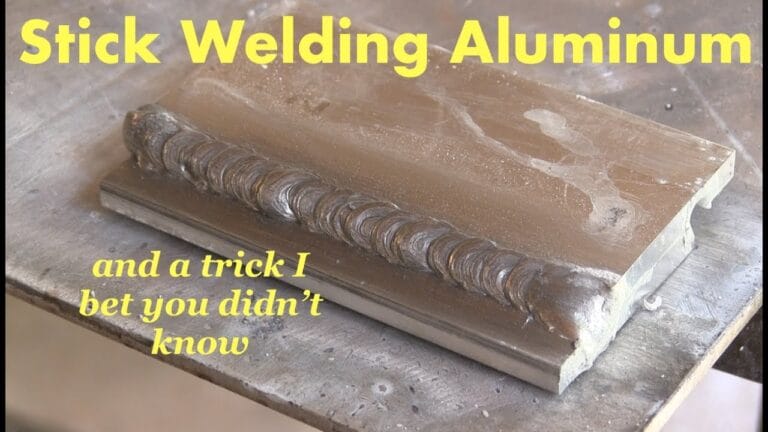

Metallurgical issues can also contribute to porosity in welding. Certain alloys or materials are more prone to porosity due to their composition or microstructure. For example, aluminum alloys and stainless steel are known to be more sensitive to porosity.

Proper selection of materials and understanding their metallurgical properties is important to mitigate the risk of porosity. Using appropriate filler metals and welding techniques for specific materials can help to minimize the occurrence of porosity. Preheating and post-weld heat treatment may also be necessary to reduce the risk of porosity in certain metallurgical situations.

In cases where porosity-prone materials or metallurgical issues cannot be avoided, alternative welding processes or specialized techniques may need to be considered.

Consulting with metallurgical professionals and experts in welding technology can provide valuable guidance and recommendations for addressing metallurgical-related porosity in welding.

Electrode Contamination

Contamination of electrodes can contribute to the formation of porosity in welding. Electrodes that are contaminated with moisture, oil, or other impurities can introduce these impurities into the weld pool, leading to porosity.

Proper storage and handling of electrodes are essential to prevent contamination.

Electrodes should be stored in a clean and dry environment, and only clean and dry gloves should be used when handling them. Inspecting electrodes for any signs of contamination, such as discoloration or unusual smells, is recommended before use.

Using electrodes from reputable manufacturers and following their recommended storage and handling procedures can help minimize the risk of electrode contamination.

Keeping an inventory of electrodes and regularly rotating them to ensure freshness and prevent prolonged exposure to moisture or contaminants is also important.

Insufficient Weld Pool Protection

Insufficient protection of the weld pool during the welding process can result in porosity. Without proper shielding or cover, the weld pool can come in contact with the surrounding atmosphere, leading to the formation of porosity.

Using appropriate welding techniques and equipment to protect the weld pool is crucial. This may include the use of backing plates, flux, or shielding gases, depending on the specific welding process and materials being used.

Proper training and knowledge of weld pool protection methods are essential for welders to ensure a sound weld and minimize the risk of porosity. Regular inspection and monitoring of the weld pool during the welding process can help to identify any issues related to insufficient protection and take corrective actions.

Tips to Minimize Porosity in Welding

Here are some tips to help minimize porosity in welding:

- Ensure materials are clean and free from moisture and contaminants before welding.

- Use the correct shielding gas flow rate and inspect gas nozzles and diffusers regularly.

- Follow proper welding procedures and techniques, including selecting appropriate welding parameters.

- Use pure and properly stored shielding gases to prevent gas contamination.

- Understand the metallurgical properties of materials and select appropriate filler metals and techniques.

- Store and handle electrodes properly to prevent contamination.

- Provide sufficient protection to the weld pool during the welding process.

Additional Causes of Porosity in Welding

-

- Gas Contamination

- Metallurgical Issues

- Electrode Contamination

- Insufficient Weld Pool Protection

Frequently Asked Questions

Welcome to our FAQ page on the topic of what causes porosity in welding! Below, you’ll find answers to some frequently asked questions on this subject. If you’re new to welding or encountering issues with porosity, this information will help you understand the factors that contribute to this common problem. Let’s dive in!

1. How does moisture affect porosity in welding?

Moisture can have a significant impact on the formation of porosity in welds. When moisture is present in the welding environment, it can vaporize during welding, turning into steam.

As the molten metal solidifies, the trapped steam can become trapped gas pockets, leading to porosity in the weld. This is why it’s crucial to properly store and handle welding materials to prevent the absorption of moisture.

To minimize porosity due to moisture, make sure to store electrodes and filler metals in moisture-resistant containers, such as dry storage ovens or air-tight bags. Additionally, avoid welding in high-humidity conditions or when the welding material is damp. Taking these precautions will help reduce the presence of moisture and minimize porosity in your welds.

2. Can improper shielding gas cause porosity in welding?

Absolutely! The selection and use of the appropriate shielding gas for the welding process are crucial in preventing porosity. When the shielding gas flow rate is too low or there are impurities in the gas, it can cause insufficient protection of the molten weld pool.

As a result, contaminants like oxygen and nitrogen can enter the weld, leading to porosity.

To avoid porosity caused by improper shielding gas, ensure that you’re using the right type of gas for your welding process. Follow the manufacturer’s guidelines and recommendations for the specific welding application.

Monitor the gas flow rate and regularly check for any impurities in the gas supply. By maintaining proper shielding gas conditions, you can significantly reduce the risk of porosity in your welds.

3. Are incorrect welding parameters a common cause of porosity?

Indeed, incorrect welding parameters can be a common culprit behind porosity in welds. When the welding parameters, such as wire feed speed, voltage, or current, are set incorrectly, it can affect the overall quality of the weld. Inadequate heat input or improper arc length can lead to incomplete fusion and inadequate melting of the base metal, resulting in porosity.

To prevent porosity caused by incorrect welding parameters, familiarize yourself with the recommended settings for your specific welding process. Refer to the welding procedure specification (WPS) or consult welding experts to ensure you’re using the appropriate parameters. Regularly monitor and adjust the welding parameters during the welding process to maintain optimal conditions and minimize porosity.

4. Can surface contaminants contribute to porosity in welding?

Absolutely! Surface contaminants like dirt, grease, paint, or rust can significantly impact the quality of welds and contribute to porosity. When these contaminants are not properly removed before welding, they can create gas pockets during the welding process, leading to porosity in the welds.

To avoid porosity caused by surface contaminants, make sure to thoroughly clean the welding surfaces before starting any welding activity. Use appropriate cleaning methods such as wire brushing, grinding, or solvent cleaning to eliminate any dirt, residue, or surface coatings. Taking these steps will help ensure a clean welding surface, reducing the chances of porosity in your welds.

5. Is electrode selection important in preventing porosity?

Definitely! The selection of the right electrode is crucial in preventing porosity and achieving high-quality welds. Different types of electrodes have varying compositions and coatings that can affect the welding process.

Using the wrong electrode or a low-quality electrode can result in incomplete fusion, trapped gases, and ultimately, porosity in the welds.

To prevent porosity caused by electrode selection, carefully choose the correct electrode for your welding application. Consider factors such as base metal composition, welding position, and required mechanical properties.

Select electrodes with a good moisture-resistance coating and those that are specifically designed for the welding process you’re using. By using the appropriate electrode, you can minimize the risk of porosity and achieve strong, durable welds.