Welcome to the world of craftsmanship in welded aluminum boats! If you’re curious about the artistry and skill that goes into creating these magnificent vessels, you’re in the right place. Let’s dive in and explore the fascinating world of building boats with aluminum.

Craftsmanship is like the secret ingredient that adds a touch of magic to anything it touches. When it comes to welded aluminum boats, craftsmanship takes center stage, combining artistry with engineering to create a vessel that not only looks stunning but performs beautifully on the water.

Imagine the skilled hands of experienced craftsmen carefully shaping and welding aluminum sheets, transforming them into the sleek and sturdy hull of a boat. Each weld, every meticulous detail, is a testament to the dedication and expertise of these artisans. Join us as we uncover the secrets behind the craftsmanship that makes these boats so special.

So, get ready for an adventure into the world of craftsmanship in welded aluminum boats. We’ll explore the techniques, the passion, and the art that makes these boats a true masterpiece.

Whether you’re a boat enthusiast or simply have a curiosity for how things are made, this journey will ignite your imagination and leave you with a newfound appreciation for the art of boat building. Let’s set sail!

Art of Craftsmanship in Welded Aluminum Boats: Mastering the Perfect Vessel

When it comes to welded aluminum boats, craftsmanship plays a vital role in ensuring their quality and durability.

Expert artisans meticulously weld each piece, creating strong and seamless joints that withstand the elements.

These boats undergo rigorous testing to ensure they meet the highest standards. Craftsmanship in welded aluminum boats involves attention to detail, precision, and skilled workmanship. It’s the mark of a boat built to last and designed to perform.

The Mastery Behind Welded Aluminum Boats

Building a welded aluminum boat requires a unique set of skills and craftsmanship that sets it apart from other boat construction methods. The process begins with carefully selecting the right grade of aluminum based on the boat’s intended use and the conditions it will face.

The aluminum is then cut, bent, and shaped into the various components of the boat’s hull and superstructure. But it’s in the welding process that true artistry comes to life.

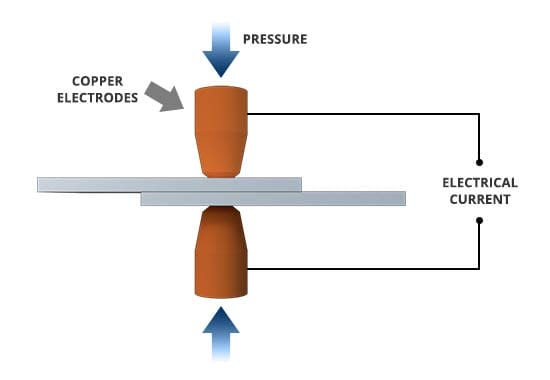

Experienced welders use their expertise to join the aluminum pieces together seamlessly, creating strong and durable bonds. Welding requires precision, as even the slightest deviation can result in weak spots or imperfections that compromise the boat’s structural integrity.

The welds must be carefully inspected and tested to ensure they meet the highest standards of quality and safety. It’s through this meticulous attention to detail that the true beauty and craftsmanship of a welded aluminum boat are revealed.

The Benefits of Crafted Excellence

When investing in a welded aluminum boat, the craftsmanship behind its construction offers a myriad of benefits. Here are just a few:

1. Unmatched Durability

Welded aluminum boats are known for their exceptional durability. The seamless welds provide a strong and rigid structure that can withstand the test of time, harsh conditions, and rigorous use. Whether you’re cruising through rough waters or exploring remote locations, you can have peace of mind knowing that your boat is built to last.

Additionally, aluminum is highly resistant to corrosion, making it a popular choice for saltwater environments. Its ability to withstand exposure to the elements, such as sun, rain, and saltwater, ensures that your welded aluminum boat will maintain its pristine condition for years to come.

2. Lightweight and Fuel-Efficient

Compared to other boat construction materials, such as fiberglass or steel, aluminum is remarkably lightweight. This reduced weight translates into improved fuel efficiency, allowing you to enjoy longer journeys without worrying about constantly refueling. The lighter weight also enhances the boat’s maneuverability and makes it easier to transport and launch.

3. Versatility and Customizability

Another advantage of welded aluminum boats is their versatility and customizability. Aluminum can easily be molded into various shapes and sizes, allowing for unique designs and personalized features. Whether you’re looking for a fishing boat with specific storage compartments or a luxurious yacht with custom interiors, the craftsmanship behind welded aluminum boats can turn your vision into a reality.

Furthermore, aluminum’s properties make it an ideal material for integrating additional features, such as swim platforms, rod holders, or hydraulic lifts. The skilled craftsmen can seamlessly incorporate these elements into the boat’s design, enhancing its functionality and comfort.

4. Superior Performance

The precision and attention to detail exhibited in the construction of welded aluminum boats directly translate into superior performance on the water. The combination of a lightweight design, strong welds, and customizable features ensures a smooth and enjoyable boating experience, regardless of the conditions.

Welded aluminum boats are renowned for their stability, maneuverability, and speed. Whether you’re indulging in watersports, going on a leisurely cruise, or participating in fishing tournaments, you can count on your boat’s performance to exceed expectations.

5. Low Maintenance

Thanks to aluminum’s resistance to corrosion and its ability to withstand the elements, maintaining a welded aluminum boat is relatively easy.

Unlike traditional wooden boats that require constant upkeep and refinishing, aluminum boats only require minimal maintenance. Regular cleaning, inspection of welds, and keeping an eye out for any signs of wear or damage are typically enough to keep your boat in top condition.

By investing in a well-crafted welded aluminum boat, you not only gain a reliable vessel but also the expertise and dedication that go behind its construction. The craftsmanship ensures that every aspect of the boat, from its structural integrity to its performance, is of the highest quality.

Strength of Expertise: What Sets Welded Aluminum Boats Apart

Within the world of welded aluminum boat construction, many factors contribute to the strength and durability of the finished vessel. These elements are what set these boats apart from other types of boats and make them the preferred choice for boat enthusiasts around the world.

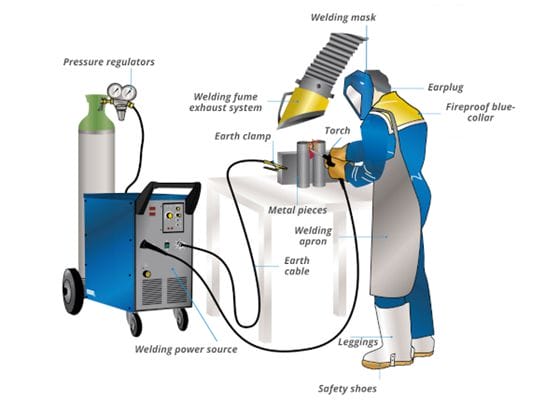

1. Superior Welding Techniques

One of the most critical aspects of constructing a welded aluminum boat is the welding technique used by the craftsmen. High-quality welds are crucial for the structural integrity and longevity of the boat. Master welders employ various welding techniques, such as Tungsten Inert Gas (TIG) or Metal Inert Gas (MIG), depending on the specific requirements of the boat’s design.

TIG welding, known for its precision and clean appearance, is often used for intricate parts and critical welds. On the other hand, MIG welding is more suitable for larger or less critical welds. Regardless of the technique chosen, skilled craftsmen meticulously weld each component, ensuring strong and flawless connections.

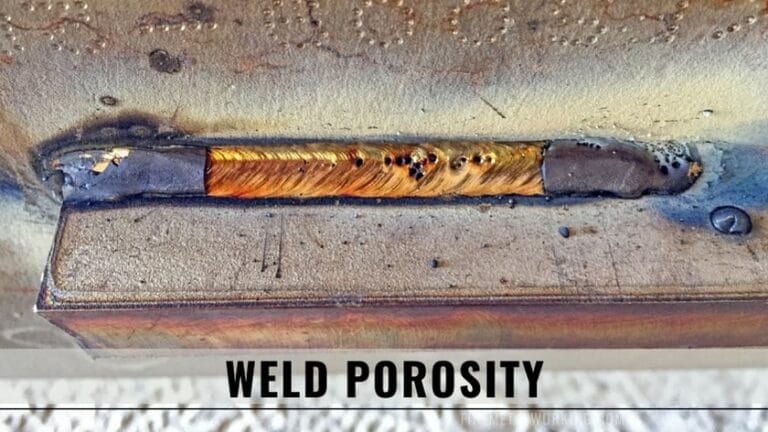

2. Thorough Quality Control

The craftsmanship behind welded aluminum boats involves more than just welding. A comprehensive quality control process is an integral part of boat construction. After each welding step, the boat undergoes rigorous inspections to identify any potential defects, such as cracks or weak spots.

Advanced inspection methods, including ultrasound or X-ray testing, are employed to ensure that the welds meet stringent quality standards. This meticulous attention to detail guarantees the highest level of safety and reliability for the boat’s owners.

3. Customized Design and Engineering

Welded aluminum boats offer endless possibilities for customization and personalized design. The expertise of boat designers and engineers plays a crucial role in translating a client’s vision into a functional and visually stunning boat.

Experienced designers work closely with clients to understand their needs and preferences, integrating unique features and design elements into the boat’s construction.

From the layout of the cabins to the selection of materials and finishes, every aspect of the boat is carefully considered to ensure it meets the highest standards of craftsmanship and aesthetics.

4. Material Selection and Construction Techniques

The selection of high-quality aluminum and the construction techniques used for welding are paramount in creating a reliable and durable boat. Craftsmen handpick the best aluminum alloys, taking into account factors such as strength, corrosion resistance, and weldability.

Furthermore, the construction techniques employed during the welding process contribute to the boat’s structural integrity.

The careful alignment of the components, the precise welding methods, and the reinforcement of critical areas ensure that the boat can withstand the toughest conditions and provide years of enjoyment.

5. Collaborative Approach

The craftsmanship behind welded aluminum boats is not a solitary endeavor. It involves the collaboration of skilled professionals, including welders, designers, engineers, and boatbuilders. This concerted effort ensures that every aspect of the boat is expertly crafted, from its hull and superstructure to its interior finishes and electrical systems.

The collaborative approach not only results in the creation of a superior boat but also fosters innovation and continuous improvement. By combining their collective expertise and knowledge, these craftsmen push the boundaries of design and construction, delivering innovative features, improved performance, and unmatched quality.

Mastering the Craft: Tips and Suggestions

If you’re considering investing in a welded aluminum boat or simply appreciate the artistry behind its construction, here are a few tips and suggestions to keep in mind:

1. Research Boat Builders

When looking for a welded aluminum boat, take the time to research reputable boat builders with a proven track record of craftsmanship and customer satisfaction. Read reviews, visit boat shows, and talk to other boat owners to gather insights and recommendations.

2. Consult with Experts

Before making a final decision, consult with experts in the field. Experienced boat designers, engineers, and boatbuilders can provide valuable advice on selecting the right boat for your needs, as well as guide you through the customization process.

3. Consider Your Needs and Intended Use

Think about how you plan to use your boat. Whether you’re an avid angler, a thrill-seeking watersports enthusiast, or simply looking for a leisurely cruising experience, communicate your needs to the boat builder. They can recommend features, layouts, and designs that best suit your requirements.

4. Inspect the Welds

When visiting the boat builder or inspecting potential boats, pay close attention to the welds. Look for clean, consistent welds with no signs of cracks or imperfections. If possible, ask the boat builder to explain the welding techniques used and their quality control processes.

5. Test Drive the Boat

If possible, arrange a test drive to experience the boat’s performance firsthand. Pay attention to its maneuverability, stability, and speed. A well-crafted welded aluminum boat should provide a comfortable and enjoyable ride, allowing you to fully appreciate the craftsmanship behind its construction.

By following these tips and suggestions, you can make an informed decision when selecting a welded aluminum boat and truly appreciate the artistry and craftsmanship that goes into creating these exceptional vessels.

The Future of Crafted Aluminium Boats: Innovation and Evolution

The art of craftsmanship in welded aluminum boats continues to evolve as boatbuilders and designers push the boundaries of innovation and technology.

With advancements in engineering, materials, and construction techniques, the future of welded aluminum boats looks promising.

1. Lightweight and Advanced Materials

The ongoing pursuit of lightweight construction materials has led to the exploration of advanced alloys and composite materials in the fabrication of welded aluminum boats.

These materials offer enhanced strength-to-weight ratios, allowing for even greater fuel efficiency and superior performance.

2. Sustainable Practices

As environmental concerns become more prevalent, boatbuilders are incorporating sustainable practices into their craftsmanship.

The use of eco-friendly materials, improved recycling methods, and energy-efficient construction techniques are all on the horizon, ensuring that the future of crafted aluminum boats aligns with environmental consciousness.

3. Integration of Technology

The future of welded aluminum boats also involves the integration of cutting-edge technology. This includes advancements in navigation systems, enhanced control interfaces, and innovative propulsion systems. These technologies will not only improve the boating experience but also further enhance safety and efficiency.

The artistry and craftsmanship behind welded aluminum boats make them more than just vessels; they are masterpieces.

From the seamless welds to the personalized designs, these boats exemplify the dedication, expertise, and passion of the craftsmen who bring them to life.

Whether you’re an avid boater or an admirer of fine craftsmanship, welded aluminum boats offer an exceptional combination of beauty, performance, and durability.

Frequently Asked Questions

Welcome to our Frequently Asked Questions section about craftsmanship in welded aluminum boats. Here, we’ll answer some common questions related to the topic, providing you with valuable insights into this specialized field.

1. What makes craftsmanship important in the construction of welded aluminum boats?

Craftsmanship plays a crucial role in the construction of welded aluminum boats because it ensures the highest quality and durability of the final product.

Skilled craftsmen pay meticulous attention to detail, ensuring that each weld is secure and every component is properly fitted. By prioritizing craftsmanship, boat builders not only enhance the structural integrity of the vessel but also increase its overall lifespan.

Additionally, the craftsmanship of welded aluminum boats ensures their ability to withstand harsh marine environments.

By utilizing their expertise, craftsmen can select the appropriate welding techniques and materials to prevent corrosion and other forms of damage. This attention to detail reinforces the boat’s longevity while keeping maintenance efforts to a minimum.

2. How can one assess the level of craftsmanship in a welded aluminum boat?

Assessing the level of craftsmanship in a welded aluminum boat can be done through careful observation and attention to the boat’s quality indicators. Begin by examining the welds for consistency and uniformity.

Look for any signs of welding defects, such as undercutting, warping, or cracking. These issues can indicate poor craftsmanship.

Inspect other aspects of the boat, such as the alignment of the hull plating, the fitting of joints, and the finishing of surfaces.

High-quality craftsmanship will be evident in precise alignments and seamless transitions between components. Additionally, take note of the overall aesthetics and attention to detail in the boat’s finishing touches. A well-crafted welded aluminum boat will exhibit flawless paintwork, polished edges, and well-fitting hardware.

3. What are the advantages of choosing a welded aluminum boat over other types?

Choosing a welded aluminum boat offers several advantages over other types of boats. First and foremost, aluminum is a lightweight material, making these boats more fuel-efficient and allowing for faster speeds on the water.

Additionally, aluminum boasts excellent corrosion resistance, ensuring the boat’s longevity even in saltwater environments.

Welded aluminum boats also provide superior structural strength, allowing them to withstand impacts and rough wave conditions.

This durability makes them suitable for various activities, such as fishing, recreational boating, and even commercial operations. Moreover, aluminum boats require minimal maintenance, thanks to the metal’s resilience and rust-free properties.

4. Can welded aluminum boats be customized to meet specific requirements?

Absolutely! Welded aluminum boats offer a high level of customization, allowing owners to meet their specific requirements. Manufacturers and skilled craftsmen can accommodate requests for different deck layouts, consoles, seating arrangements, and storage options.

Furthermore, customization extends to the boat’s features and accessories. Individuals can choose the type of propulsion system, electronics, and even fishing amenities they desire. The flexibility in customization options allows boat owners to tailor their vessels to their unique needs and preferences.

5. How long can a well-crafted welded aluminum boat last?

A well-crafted welded aluminum boat, when properly maintained, can last for several decades. The durability of aluminum combined with skilled craftsmanship ensures that these boats can withstand the test of time. However, regular maintenance and corrosion prevention are essential to maximize the boat’s lifespan.

By regularly inspecting the boat for any damages, promptly addressing them, and following proper maintenance procedures, owners can enjoy their welded aluminum boats for many years. Regular cleaning, both interior and exterior, along with routine checks on mechanical components, will help ensure the boat’s longevity and optimal performance.

Craftsmanship in welded aluminum boats is important because it ensures durability and safety. Skilled welders use precise techniques to create strong and reliable boat structures.

Welded aluminum boats are lightweight, corrosion-resistant, and easy to maintain, making them popular in various industries such as fishing and recreation.

To achieve the highest quality, careful attention is given to details like weld penetration and seam quality. Investing in well-crafted welded aluminum boats is worth it because they offer long-lasting performance and enjoyable experiences on the water.

Craftsmanship matters in welded aluminum boats. Skilled welders create strong, durable, and safe boat structures. These boats are lightweight, corrosion-resistant, and require minimal maintenance. By paying attention to details, like weld quality, the result is a high-quality boat that provides years of reliable performance and fun on the water.