Can you MIG weld stainless steel? If you’ve ever wondered about this fascinating welding technique, you’ve come to the right place! MIG welding, also known as Gas Metal Arc Welding (GMAW), is a popular method for joining metal components. But can it be used with stainless steel? Let’s dive in and explore the possibilities together!

MIG welding is a versatile and efficient welding process that allows you to create strong and durable bonds between metal pieces. But when it comes to stainless steel, there are some key considerations to keep in mind. Stainless steel has unique properties that require special attention during the welding process.

In this article, we’ll explore the ins and outs of MIG welding stainless steel. From understanding the challenges to discovering the best techniques, we’ll cover it all. So, whether you’re a curious hobbyist or an aspiring welder, get ready to learn everything you need to know about MIG welding stainless steel!

MIG welding is a versatile process that can be used to weld stainless steel. Here are some essential tips to successfully MIG weld stainless steel:

- Use a stainless steel wire and shielding gas suitable for stainless steel.

- Clean the surface of the stainless steel thoroughly.

- Adjust the welding machine settings for stainless steel.

- Keep the welding gun at the correct angle and maintain a steady travel speed.

- After welding, clean the welded area to remove any discoloration or oxide buildup.

Can You Mig Weld Stainless Steel?

When it comes to welding, different metals require different techniques. One common question that arises is whether or not you can MIG (Metal Inert Gas) weld stainless steel. Stainless steel is a popular choice in various industries due to its corrosion resistance and aesthetic appeal. In this article, we will explore the feasibility of MIG welding stainless steel, the challenges involved, and the best practices to ensure successful welds.

Understanding Stainless Steel

Before diving into MIG welding stainless steel, it is essential to understand the properties of this unique metal. Stainless steel is an alloy composed primarily of iron, chromium, and nickel. The addition of chromium and nickel enhances its resistance to corrosion, making it ideal for applications where durability is crucial. However, stainless steel has a higher thermal conductivity and lower thermal expansion rate than carbon steel, making it more challenging to weld.

When MIG welding stainless steel, it is crucial to select the appropriate filler wire that matches the base metal’s grade. Commonly used filler wires include ER308, ER309, and ER316, depending on the specific stainless steel grade being welded. These filler wires ensure the proper chemical composition and mechanical properties of the weld joint, resulting in a strong and durable bond.

Further, it is essential to note that stainless steel has a thin, protective oxide layer on its surface, which can affect the weld. To mitigate this, the weld area should be cleaned before welding, using methods like wire brushing or stainless steel cleaning solutions. Proper surface preparation ensures optimal weld quality and reduces the risk of defects.

The Challenges of MIG Welding Stainless Steel

MIG welding stainless steel presents several challenges that welders must overcome to achieve high-quality welds. One of the main challenges is the higher thermal conductivity of stainless steel compared to carbon steel. This means that stainless steel dissipates heat more rapidly, making it more susceptible to distortion and warping during the welding process.

Another challenge is the formation of chromium carbides along the grain boundaries of stainless steel when heated above a certain temperature range. This phenomenon, known as sensitization, can lead to intergranular corrosion and reduced corrosion resistance in the heat-affected zone (HAZ) of the weld. To prevent sensitization, it is crucial to use low heat input during welding and perform post-weld heat treatment processes like solution annealing or stabilization.

Furthermore, stainless steel’s lower thermal expansion rate can result in a higher tendency for weld cracking, especially if improper welding techniques or excessive heat input are used. It is essential to control the welding parameters, such as the welding current, voltage, and the speed of the wire feed, to minimize the risk of cracks forming in the weld joint.

Best Practices for MIG Welding Stainless Steel

While MIG welding stainless steel can be more challenging than welding carbon steel, following best practices can help ensure successful welds:

1. Use the Correct Shielding Gas

Stainless steel requires a shielding gas with a high percentage of argon to protect the weld from atmospheric contamination. Typically, a mixture of 98% argon and 2% carbon dioxide or a 100% argon gas is used for MIG welding stainless steel. The shielding gas helps maintain the stable arc and prevents oxidation of the weld bead.

2. Select the Right Filler Wire

Choosing the correct filler wire is crucial for achieving strong and corrosion-resistant welds. The choice of filler wire depends on the specific stainless steel grade being welded. ER308 is used for welding 304 stainless steel, ER309 for welding 309 and 316L stainless steel, and ER316 for welding 316 stainless steel. Consult the filler wire manufacturer’s recommendations for the best results.

3. Control Heat Input

Proper heat control is essential when MIG welding stainless steel. Excessive heat can lead to distortion, warping, and the formation of sensitization or cracks. Adjust the welding parameters, such as the welding current and voltage, to ensure a controlled heat input and avoid overheating the base metal.

4. Clean the Weld Area

Before welding stainless steel, it is critical to clean the weld area thoroughly. Use a stainless steel wire brush or a specialized cleaning solution to remove any surface contaminants, oils, or oxides that could negatively affect the weld quality. Cleaning the weld area helps promote proper fusion and adhesion between the base metal and the filler wire.

5. Perform Post-Weld Heat Treatment

In some cases, post-weld heat treatment processes may be necessary to ensure the desired properties of the weld joint. Solution annealing or stabilization can help eliminate sensitization and improve the corrosion resistance of the weld. Consult the material specifications or a welding engineer for guidance on the appropriate heat treatment processes for the specific stainless steel grade.

6. Practice and Seek Professional Guidance

MIG welding stainless steel requires skill and experience. If you are new to welding or unfamiliar with MIG welding stainless steel, it is recommended to practice on scrap pieces or seek guidance from a professional welder. They can provide valuable insights, tips, and techniques to help you achieve optimal results.

Benefits of MIG Welding Stainless Steel

MIG welding stainless steel offers several advantages, making it a preferred choice in various industries:

1. Corrosion Resistance

Stainless steel’s inherent corrosion resistance makes it ideal for applications where exposure to harsh environments, moisture, or corrosive substances is a concern. MIG welding ensures robust and durable welds, maintaining the stainless steel’s corrosion-resistant properties.

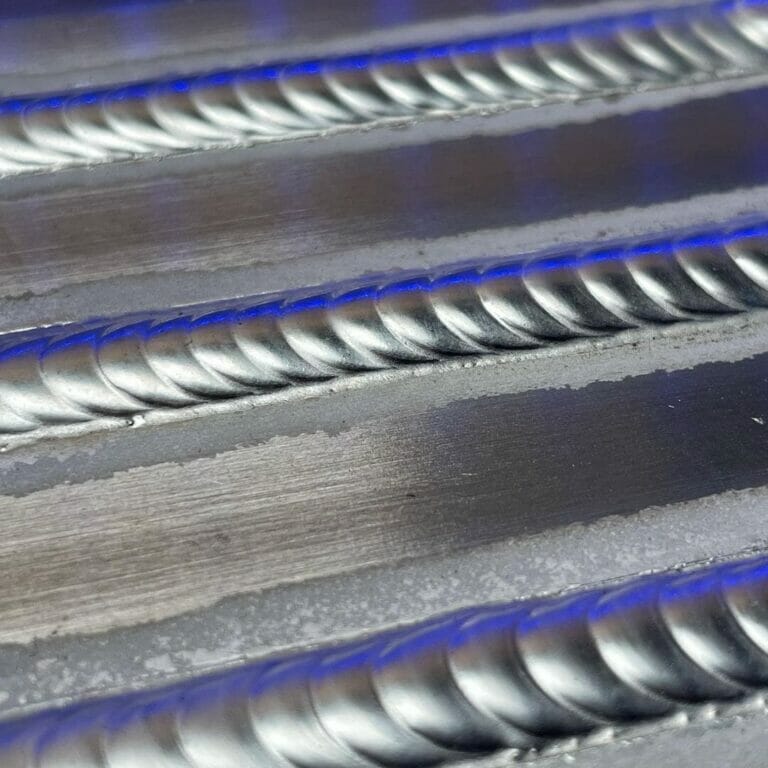

2. Aesthetic Appeal

Stainless steel is known for its attractive appearance and is commonly used in architectural, decorative, and cosmetic applications. MIG welding allows for precise control and clean weld beads, ensuring a visually appealing finished product.

3. Strength and Durability

When properly welded, stainless steel exhibits excellent strength and durability. MIG welding offers a reliable and efficient method to achieve strong weld joints, enhancing the overall structural integrity of stainless steel components.

FAQs

1. Can you MIG weld stainless steel without gas?

No, MIG welding stainless steel requires a shielding gas, typically a mixture of argon and carbon dioxide or pure argon, to protect the weld from atmospheric contamination and oxidation.

2. Can you use stainless steel wire for MIG welding?

No, stainless steel wire is not recommended for MIG welding. Instead, stainless steel wire is used as the filler material to join the stainless steel base metal.

3. Can you spot weld stainless steel?

Yes, spot welding can be used to join stainless steel sheets or components. Spot welding utilizes electrical resistance to create localized welds, ensuring a strong bond between the metals.

Wrap-Up:

In conclusion, MIG welding stainless steel is indeed possible, although it comes with its challenges. Understanding the properties of stainless steel, selecting the appropriate filler wire, controlling heat input, and practicing proper welding techniques are crucial for achieving successful and high-quality welds. By following best practices and seeking professional guidance when needed, you can harness the benefits of MIG welding stainless steel, such as its corrosion resistance, aesthetic appeal, and strength. Remember to always prioritize safety and adhere to industry standards to ensure optimal results. Happy welding!

Key Takeaways: Can You Mig Weld Stainless Steel?

- MIG welding can be used to weld stainless steel.

- Stainless steel requires special shielding gas during MIG welding.

- Using the correct filler wire is important when MIG welding stainless steel.

- Proper cleaning and preparation of the stainless steel surface is crucial for successful MIG welding.

- MIG welding stainless steel requires higher heat compared to other metals.

Frequently Asked Questions

Welcome to our Frequently Asked Questions section about MIG welding stainless steel. Here, we’ll address common queries regarding this topic to help you gain a better understanding. Read on to learn more!

Can I use a MIG welder to weld stainless steel?

Yes, you can use a MIG welder to weld stainless steel. MIG welding, also known as Gas Metal Arc Welding (GMAW), is a popular welding method for its ease of use and versatility. With the right equipment and techniques, you can achieve strong and durable welds on stainless steel. However, it’s important to note that stainless steel has different properties compared to other metals, so there are certain considerations to keep in mind when MIG welding it.

First, you need to use the appropriate shielding gas. Stainless steel requires a specific gas mixture, usually containing high levels of argon, to protect the weld puddle and prevent oxidation. Additionally, stainless steel has a higher thermal conductivity, so proper heat control is crucial to prevent distortion or burn-through. By adjusting the settings on your MIG welder and using the right techniques, you can successfully MIG weld stainless steel.

Do I need to prepare stainless steel before MIG welding?

Yes, proper preparation is essential for successful MIG welding of stainless steel. Before welding, it’s crucial to clean the stainless steel surface thoroughly. This helps remove any contaminants, such as oil, grease, or dirt, which can affect the quality of the weld. Use a stainless steel wire brush or a dedicated cleaning solution to ensure a clean and oxide-free surface.

Additionally, stainless steel has a protective layer of chromium oxide that can form during exposure to air. This layer needs to be removed before welding to ensure proper fusion. You can eliminate the oxide layer by using a stainless steel wire brush, a dedicated stainless steel cleaner, or even grinding if necessary. By properly preparing the stainless steel surface, you’ll create optimal conditions for a strong and reliable weld.

What type of filler wire should I use for MIG welding stainless steel?

When MIG welding stainless steel, it’s crucial to use the correct filler wire. The most commonly used filler wire for stainless steel MIG welding is the ER308L wire. This wire is specifically designed for welding austenitic stainless steels, like 304 and 304L grades. It offers excellent corrosion resistance and has a low carbon content to prevent carbide precipitation, which can lead to intergranular corrosion.

It’s important to match the filler wire composition to the base metal to ensure compatibility and achieve the desired weld characteristics. Different stainless steel grades may require different filler wires, so consult the manufacturer’s recommendations or seek expert advice to determine the appropriate filler wire for your specific project. Using the correct filler wire will help you achieve strong, durable, and corrosion-resistant welds on stainless steel.

What are some common challenges when MIG welding stainless steel?

MIG welding stainless steel can present a few challenges compared to welding other metals. One common challenge is the tendency for stainless steel to warp or distort under heat. Stainless steel has a higher thermal conductivity, meaning it can dissipate heat quickly and expand more easily. To minimize the risk of distortion, it’s important to control the heat input while welding. Adjusting the welding speed, using lower voltage, and employing proper techniques like ‘stitch’ or intermittent welding can help mitigate distortion.

Another challenge is preventing oxidation during the welding process. Stainless steel is highly sensitive to contamination and requires the use of appropriate shielding gases, typically a mixture of argon and other gases, to protect the weld puddle from atmospheric gases. Proper gas flow rates and technique are crucial for achieving clean and strong welds. Additionally, stainless steel requires clean surfaces and the removal of oxide layers before welding to ensure proper fusion and prevent defects.

Can stainless steel be MIG welded without any issues?

MIG welding stainless steel can be done successfully with the right knowledge and techniques. However, it’s important to note that stainless steel has unique properties and welding requirements. Failing to follow proper procedures can result in issues such as poor weld quality, distortion, or inadequate corrosion resistance.

By understanding the characteristics of stainless steel and implementing the appropriate welding techniques and procedures, you can achieve excellent results. Practice, attention to detail, and a solid understanding of MIG welding principles on stainless steel will help you overcome any potential issues and create strong, high-quality welds.

Summary

MIG welding stainless steel can be tricky, but it is possible with the right equipment and technique. The main challenge is preventing contamination and achieving proper weld penetration. It’s important to use the correct shielding gas and wire, clean the surfaces thoroughly, and adjust the settings for stainless steel. With practice and some patience, you can successfully MIG weld stainless steel projects.

In conclusion, MIG welding stainless steel requires attention to detail and knowledge of the right techniques. By following the proper steps and using the appropriate tools, you can achieve strong and reliable welds on stainless steel materials. So, don’t be afraid to give it a try and keep practicing to improve your skills. Happy welding!