Picture this: you’re faced with a tough job, and you need to turn the tables in your favor. That’s where wrench techniques come into play. In this article, we’ll explore the art of using wrenches for those challenging tasks.

Let’s dive right in and discover the secrets to handling tough jobs with ease. With the right wrench techniques, you’ll be able to conquer any project that comes your way.

Whether you’re a DIY enthusiast or a budding handyman, this guide will equip you with the knowledge and skills to tackle those tricky jobs head-on. So grab your wrenches, and let’s get started on this exciting journey of turning the tables!

Wrench Techniques for Tough Jobs

Strong Hold Wrenches vs. Quick Twist Tools: A Clash of Power and Precision! Let’s compare these two wrench techniques for tough jobs.

| Strong Hold Wrenches | Quick Twist Tools |

| 1. Superior gripping power | 1. Lightning-fast operation |

| 2. Adjustable torque settings | 2. Compact and portable |

| 3. Ergonomic handle design | 3. Versatile for various tasks |

| 4. Durable construction | 4. Precise and accurate results |

| 5. Anti-slip technology | 5. Time-saving and efficient |

1) The Basics: Getting a Grip

When using a wrench, the first step is to establish a solid grip on the tool. This ensures that you have full control and minimizes the risk of slipping, which can lead to injuries or stripped bolts. Start by placing your hand on the handle, with your fingers wrapped firmly around it. Make sure your grip is comfortable and allows for a good range of motion.

If you’re dealing with a particularly stubborn bolt, consider using a wrench with a non-slip grip or adding additional padding to the handle.

Once you have a firm grip, position the wrench head securely over the bolt or nut you’re working on. Align the jaws of the wrench parallel to the flats of the bolt or nut to maximize contact and minimize the risk of rounding off the edges.

Apply steady pressure in the direction you want to turn, using your other hand to hold the object you’re working on steady. Remember not to overexert yourself – using proper technique is more important than brute force.

As you gain experience, you’ll develop a feel for how much force to apply and when to adjust your grip. It’s important to strike a balance between exerting enough pressure to get the job done and avoiding excessive force that could damage the bolt or the surrounding components.

2) Leverage: Extending Your Reach

One of the key advantages of using a wrench is the ability to leverage your strength and apply more torque to the fastener you’re working on. By extending your reach, you can multiply the force exerted and make it easier to loosen or tighten stubborn bolts. The longer the handle of the wrench, the greater the leverage you can achieve, but keep in mind that longer handles may also require more effort to operate.

To maximize leverage, position your hand as far away from the bolt or nut as possible, while still maintaining a good grip.

For even more leverage, you can use a pipe or an extension bar to extend the handle of the wrench. This technique is particularly useful when dealing with stuck or rusted bolts that require extra force to break free.

It’s worth noting that while leverage can be beneficial, there is a limit to how much force you can safely apply without risking damage to the fastener or the tool itself. Always refer to manufacturer guidelines and exercise caution when using extensions or additional leverage.

3) Box-End vs. Open-End: Understanding the Difference

When it comes to wrenches, you have the choice between box-end and open-end designs. Each type has its advantages and is better suited for specific applications. Understanding the differences between them will help you choose the right wrench for the job.

A box-end wrench features a closed loop at one or both ends, with six or twelve points of contact on the bolt or nut. This design provides a secure grip and is less likely to slip, making it ideal for working with stubborn or hard-to-reach fasteners.

However, box-end wrenches have limited flexibility and require more space to operate, so they may not be suitable for tight or confined areas.

On the other hand, open-end wrenches have U-shaped jaws that grip the flats of the fastener. This design allows for easier access in tight spaces and provides a greater range of motion.

Open-end wrenches are often used in situations where speed and convenience are important. However, they can be prone to slipping, especially when dealing with particularly tight or rusted bolts.

4) Adjustables: The Versatile Solution

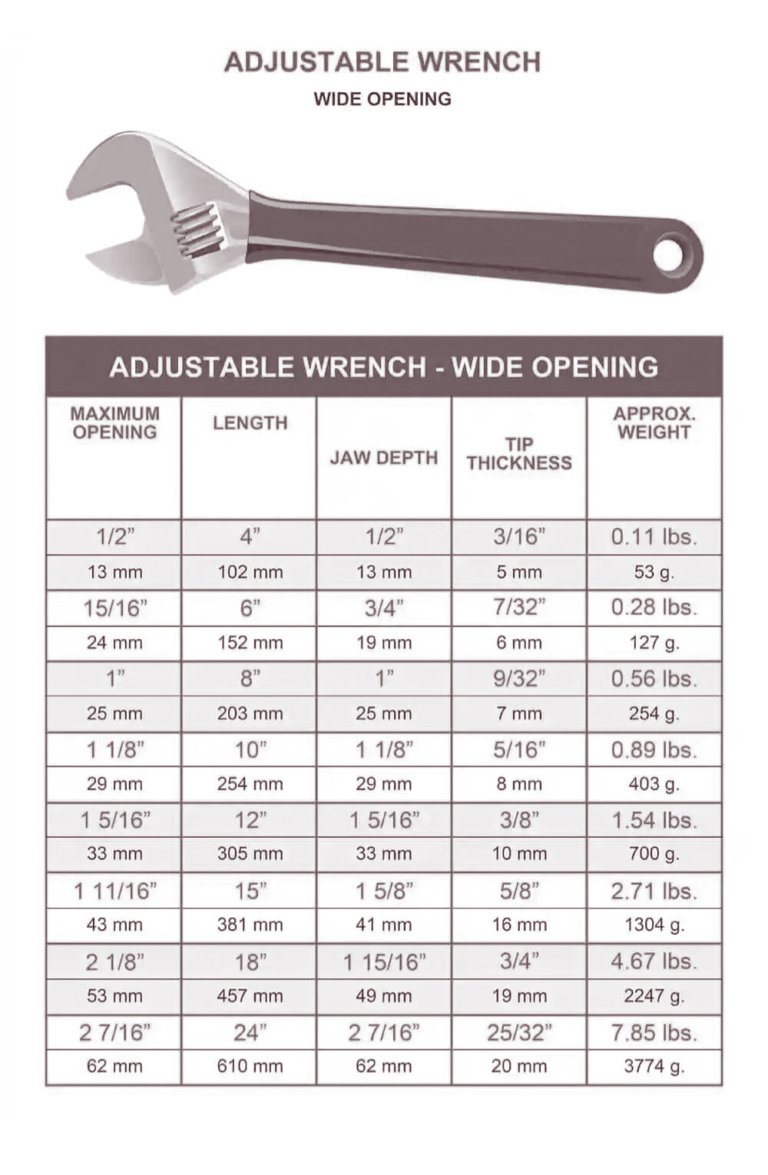

When you’re faced with a wide range of bolt or nut sizes, an adjustable wrench can be a valuable addition to your toolkit. Also known as a crescent wrench or an adjustable spanner, this versatile tool features a jaw that can be adjusted to accommodate different sizes.

To use an adjustable wrench effectively, start by loosening the adjusting screw located near the joint of the wrench. This will allow the jaws to move freely.

Next, open the jaws slightly wider than the size of the fastener you’re working on. Position the jaws over the bolt or nut and tighten the adjusting screw to secure the grip. Make sure the jaws are snugly fitted to minimize the risk of slipping.

While adjustable wrenches offer convenience and flexibility, they can be less accurate and provide less gripping power compared to fixed-size wrenches. Hence, it’s important to use them properly and ensure that the jaws are fully engaged with the fastener to avoid rounding off the edges.

5) Specialty Wrenches: The Right Tool for the Job

While standard wrenches are suitable for most tasks, certain specialized wrenches are designed to tackle specific challenges more effectively. Having a few of these specialty wrenches in your arsenal can make a world of difference when faced with particularly tough jobs.

One such example is the pipe wrench, which features a self-tightening grip that can handle rounded or irregularly shaped objects, such as pipes or fittings.

Pipe wrenches are commonly used in plumbing and mechanical work, and they come in various sizes to accommodate different diameters. Another specialized wrench is the torque wrench, which allows for precise control over the amount of torque applied to a fastener.

This is especially important when working on sensitive or delicate components that require specific torque specifications.

Other specialized wrenches include the ratcheting wrench, which allows for quick, continuous tightening or loosening without the need to remove and reposition the tool, and the flare nut wrench, which is designed to grip tubing nuts without damaging the surface. By investing in these specialty wrenches, you’ll have the right tool for any job that comes your way.

6) Advanced Techniques: Breaking Barriers

There may be instances where even the most basic wrench techniques won’t suffice. For particularly stubborn or rusted bolts, you may need to employ more advanced techniques to break through the barriers. One such technique is the use of penetrating oil.

Apply a generous amount of penetrating oil – such as WD-40 or PB Blaster – to the fastener and allow it to work its way into the threads. This will help loosen the rust and corrosion, making it easier to turn the bolt.

If penetrating oil doesn’t do the trick, you can try using heat to expand the metal and break the bond. Use a handheld propane torch or an electric heat gun to apply heat directly to the bolt or surrounding area.

Be cautious not to overheat other components or ignite any flammable substances. The expansion caused by the heat should help break the rust or corrosion, allowing you to turn the bolt more easily.

For severely stripped or rounded-off bolts, you may need to resort to using a bolt extractor. This specialized tool is designed to grip onto the rounded or damaged head of the bolt, allowing you to turn it out. Bolt extractors come in various sizes and designs, so make sure to select the appropriate one for your specific needs.

7) Maintenance and Care: Prolonging the Lifespan

Like any other tool, wrenches require regular maintenance and care to ensure they perform optimally and have a long lifespan. After each use, wipe down your wrenches to remove any dirt, grease, or debris. This will help prevent contaminants from building up and affecting the performance of the tool.

Periodically inspect your wrenches for signs of wear or damage, such as bent handles, worn jaws, or loose adjustment mechanisms. Replace any worn or damaged parts to maintain the tool’s functionality and safety.

Additionally, lubricating your wrenches can help prevent rust and corrosion, as well as keep the moving parts smooth and easy to operate. Apply a small amount of lubricant to the pivot point and any other movable parts of the wrench. Be sure to use a lubricant that is compatible with the material of your wrench.

Choosing the Right Wrench for the Job

Now that you’ve learned the ins and outs of wrench techniques for tough jobs, it’s important to remember that not all wrenches are created equal.

Choosing the right wrench for the job can save you time, effort, and frustration. Consider factors such as the size of the fastener, the accessibility of the area, and the level of torque required.

Wrench Techniques for Safety and Efficiency

Turning the tables on tough jobs requires a combination of skill, knowledge, and the right tools. By mastering the wrench techniques outlined in this article, you’ll be well-equipped to tackle even the most challenging tasks with confidence, safety, and efficiency.

Investing in Quality Tools

Lastly, remember that investing in quality wrenches and tools is essential for your success. Cheap, low-quality tools may seem appealing due to their lower price point, but they are often less durable and can compromise your safety. Opt for reputable brands known for their quality and reliability. Your tools are not just an expense but an investment that will pay off in the long run.

Frequently Asked Questions

In this section, we will answer some common questions about wrench techniques for tough jobs.

1. How can I loosen a rusted nut or bolt?

Loosening a rusted nut or bolt can be tricky, but there are a few techniques you can try. First, spray the nut or bolt with a penetrating oil like WD-40 and let it sit for a few minutes to help break down the rust. Then, use a wrench with a long handle for better leverage.

Tap the wrench lightly with a hammer to help loosen the rust. If the nut or bolt is still stuck, try using heat. Apply heat directly to the area using a propane torch or a heat gun to expand the metal, making it easier to turn.

Remember to use caution when using heat and always wear protective gloves. If none of these techniques work, you may need to use a breaker bar or seek assistance from a professional.

2. What is the best way to remove a stripped bolt?

Dealing with a stripped bolt can be frustrating, but there are a few methods to remove it. First, try using a pair of pliers or vise grips to grip onto the edges of the bolt head and turn it counterclockwise.

If that doesn’t work, you can also try using a rubber band. Place the rubber band over the stripped bolt head and press it firmly into the recess. Then, turn the bolt counterclockwise. The rubber band can provide extra grip and traction.

If these methods don’t work, you can also use a bolt extractor, which is a tool specifically designed to remove stripped bolts. Make sure to choose the correct size extractor for your bolt and follow the manufacturer’s instructions carefully.

3. How can I prevent rounding off bolt heads?

Rounding off bolt heads can be avoided by using the right tools and techniques. First, make sure you are using the correct size wrench or socket that fits snugly on the bolt head.

It’s important not to force a wrench that is too small or too big, as this can lead to rounding off the corners. Apply steady and even pressure while turning the bolt, without sudden jerks or excessive force.

Using a six-point wrench or socket instead of a twelve-point can also help prevent rounding off bolt heads. Six-point tools provide more points of contact on the bolt head, distributing the force more evenly and reducing the risk of rounding.

Finally, maintaining your tools in good condition, including keeping wrenches clean and avoiding worn-out tools, can further prevent rounding off bolt heads.

4. What is the difference between an adjustable wrench and a socket wrench?

An adjustable wrench and a socket wrench are both versatile tools but have some differences. An adjustable wrench, also known as a crescent wrench, has a fixed jaw and an adjustable jaw that can be moved to fit different sizes of nuts and bolts. It is a handy tool for general use and can be easily adjusted by turning a knurled wheel.

On the other hand, a socket wrench uses separate sockets of various sizes that attach to the wrench handle. It provides a more secure and precise fit on the fastener compared to an adjustable wrench. Socket wrenches are commonly used in automotive and mechanical applications where specific torque settings are required.

5. How can I tighten a stubborn bolt without stripping it?

To tighten a stubborn bolt without stripping it, start by using the correct size wrench or socket that fits securely on the bolt head.

Apply steady and even pressure while turning the bolt, avoiding sudden jerks or over-tightening. If the bolt is resistant, try using a lubricant, such as a penetrating oil, to reduce friction and make it easier to turn.

It’s important not to force the bolt if it’s not moving. Using a breaker bar or an extension pipe for increased leverage can help, but still, be cautious not to apply excessive force. If you encounter difficulty, seeking professional assistance may be the best option to avoid damaging the bolt or surrounding components.

So, here’s what you need to know about turning the tables and using wrench techniques for tough jobs. First, remember to choose the right type of wrench for the task at hand. Whether it’s adjustable, socket, or pipe wrench, using the correct one will make your job a lot easier.

Second, make sure you have a good grip on the wrench and use proper body positioning to maximize your strength. This will help you apply more force and loosen those stubborn nuts and bolts.

Lastly, if you’re stuck with a rusted or seized fastener, try applying heat or using penetrating oil to make it easier to turn. With these tips, you’ll be able to tackle tough jobs like a pro and get the job done!