Is welding hard? If you’ve ever wondered about this hands-on skill, you’re in the right place! Whether you’ve seen sparks fly in movies or witnessed a welder in action, you might be curious about the difficulty level of this trade. Well, strap on your safety goggles and get ready to dive into the world of welding!

Welding is an art that transforms metal pieces into sturdy structures through a process called fusion. But don’t let the word “fusion” scare you away.

While welding may seem challenging at first, with practice and proper training, anyone can master this craft. So, let’s explore the ins and outs of welding and find out just how hard it really is.

From constructing buildings to crafting sculptures, welding offers a wide range of possibilities and career opportunities. So, if you’re ready to spark your curiosity and learn more about welding, read on to discover the truth behind the question: is welding hard?

Is Welding Hard?

Welding can be challenging for beginners, but with practice and the right resources, it becomes easier. Learning the necessary techniques and safety precautions is important.

Take advantage of welding classes or tutorials to get started. Invest in quality welding equipment and protective gear. Practice welding on scrap metal before moving on to major projects. Remember, with dedication and perseverance, anyone can become proficient in welding!

The Basics of Welding

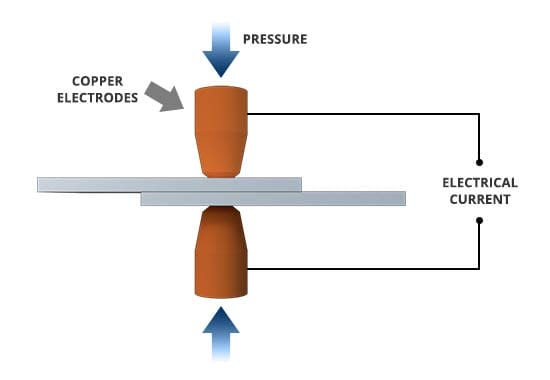

Welding involves the use of heat and pressure to create a strong bond between metal pieces. The process requires a welding machine, which generates the heat necessary to melt the metal, and a filler material, known as the welding rod or wire, to create the bond.

Welding can be performed using various techniques, such as arc welding, MIG welding, TIG welding, and more. Each technique has its own unique characteristics and applications.

To become proficient in welding, you will need to familiarize yourself with the different welding techniques, understand the properties of various metals, and learn the proper safety precautions.

While it may seem overwhelming at first, with practice and dedication, anyone can develop the skills necessary to become a skilled welder.

The Learning Process

Learning to weld is a journey that requires patience and perseverance. It is not something that can be mastered overnight. However, with the right mindset and guidance, you can become proficient in welding.

Here are the key steps to becoming a skilled welder:

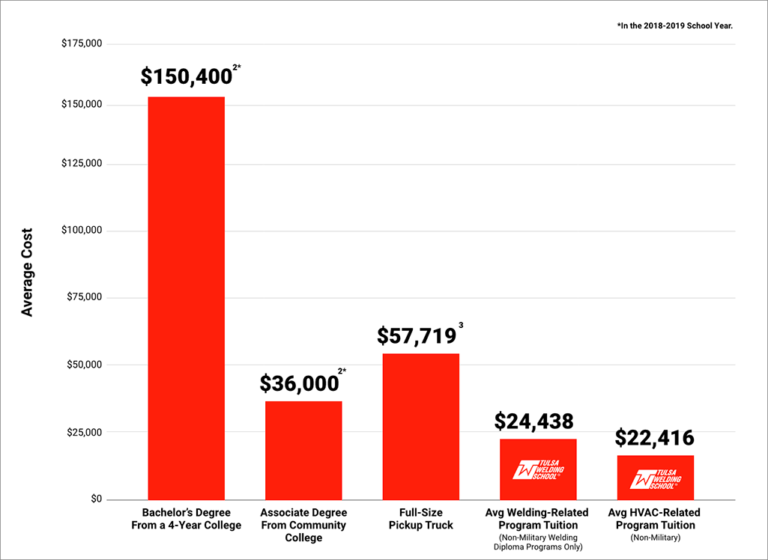

1. Education: Start by enrolling in a welding course or program. These programs are designed to provide you with a solid foundation in welding techniques, safety protocols, and industry standards. You will have the opportunity to gain hands-on experience and learn from experienced instructors.

2. Practice: Just like any other skill, welding requires practice. Set up a welding workstation at home or find opportunities to practice in a workshop.

Start with simple projects and gradually work your way up to more complex ones. Remember, practice makes perfect, and the more you weld, the better you will become.

3. Certification: Once you have gained some experience and honed your skills, consider obtaining a welding certification. This certification serves as proof of your competence and can open up new career opportunities.

There are various certification bodies that offer exams to test your welding skills. Prepare for the exam by practicing the specific welding techniques that will be assessed.

Tips for Mastering Welding

Becoming a skilled welder is a continuous process, and there are a few tips that can help you along the way. Here are some expert tips to help you master the art of welding:

1. Safety first: Always prioritize safety when welding. Wear appropriate protective gear, such as a welding helmet, gloves, and a flame-resistant jacket. Ensure proper ventilation in your workspace and never weld in confined spaces.

2. Master the fundamentals: Develop a strong foundation by mastering the basic welding techniques. Focus on maintaining a stable arc, controlling the welding puddle, and achieving proper penetration. These fundamentals will form the building blocks of your welding skills.

3. Learn from others: Seek guidance from experienced welders and take advantage of their knowledge and expertise. Attend welding workshops, participate in online forums, and network with professionals in the welding industry. Learning from others’ experiences can help you avoid common mistakes and accelerate your learning curve.

4. Practice different materials: Experiment with welding different types of metals and materials. Each material requires specific welding techniques and settings. By practicing on a variety of materials, you will expand your skills and become a versatile welder.

5. Stay updated: The field of welding is constantly evolving, with new techniques and technologies being introduced. Stay up to date with the latest advancements by reading industry publications, attending trade shows, and participating in professional development courses. Continuous learning will help you stay competitive and improve your welding skills.

Career Opportunities in Welding

Welding offers a wide range of career opportunities, with high demand for skilled welders in various industries. Here are some of the career paths you can pursue as a welder:

1. Construction: Welders play a crucial role in the construction industry, joining metal components to create structures like bridges, buildings, and pipelines. These professionals are in high demand, especially in booming construction markets.

2. Manufacturing: Welders are vital in the manufacturing sector, where they contribute to the production of machinery, automobiles, and consumer goods. Skilled welders are needed to create precise and durable welds for manufacturing processes.

3. Oil and gas industry: The oil and gas industry relies heavily on welding for pipelines, storage tanks, and offshore structures. Welders in this industry undergo specialized training and often work in challenging environments.

4. Aerospace and aviation: Welding is an essential process in the aerospace and aviation industries, where aircraft parts and components must meet strict quality standards. Welders in this field require advanced skills and knowledge in welding specialty metals like aluminum and titanium.

5. Art and sculpture: Welding also offers opportunities for artistic expression. Many artists and sculptors use welding techniques to create intricate metal sculptures and unique works of art.

Whether you choose to pursue a career in welding or simply want to acquire the skills of a hobbyist, mastering welding can open up a world of possibilities.

With dedication, practice, and a love for the craft, you can become a skilled welder and create strong and lasting connections between metal pieces. So, don your welding helmet, pick up your welding torch, and let the sparks fly as you embark on your welding journey!

Frequently Asked Questions

Are you curious about welding and wondering if it’s a difficult skill to master? Look no further – we’ve got answers to your burning questions!

What are the challenges of learning welding?

Learning welding can present some challenges, but with patience and practice, it is a skill that can be mastered. One major challenge is getting accustomed to handling the welding equipment and understanding how to use it safely and effectively.

It can initially be daunting to control the heat, manage the welding process, and create strong, durable welds. However, with proper training and experience, these challenges can be overcome.

Additionally, mastering different welding techniques and understanding the properties of various metals can also be a learning curve. Each welding process requires its own set of skills and knowledge.

While it may seem overwhelming at first, breaking down the learning process into smaller steps and seeking guidance from experienced welders can help overcome these challenges.

Is welding physically demanding?

Welding does require physical exertion, but it is not necessarily physically demanding in the traditional sense. It involves prolonged standing, holding welding equipment, and frequently working in various positions, such as kneeling or crouching.’

While this can lead to fatigue and strain on the body, it can be managed with proper training and adopting ergonomic techniques.

It is important to maintain a good posture and use appropriate safety gear to minimize physical strain. Regular breaks and stretching exercises are also recommended to prevent muscle fatigue.

Overall, welding can be physically demanding, but with the right precautions and practices, it can be done safely without excessive strain on the body.

Can anyone learn to weld?

Absolutely! Anyone with a willingness to learn and dedication can acquire welding skills. It does not require any specific educational background or prior experience. However, it is important to receive proper training and guidance to ensure safety and proficiency.

Many technical schools, vocational programs, and community colleges offer welding courses for beginners.

These programs provide the necessary knowledge, hands-on practice, and certification opportunities. With a strong desire to learn and the right resources, anyone can embark on a rewarding journey to become a skilled welder.

How long does it take to become proficient in welding?

Becoming proficient in welding varies depending on the individual, the amount of time dedicated to learning, and the complexity of the welding processes. While some basic welding skills can be acquired in a matter of weeks or months, gaining expertise in advanced techniques may take several years.

Consistent practice is key to becoming proficient. It is recommended to start with simpler welding techniques and gradually progress to more complex ones.

Seeking guidance from experienced welders, attending workshops, and participating in hands-on training can greatly expedite the learning process. With dedication, practice, and continuous learning, one can become proficient in welding over time.

Are there any safety considerations in welding?

Safety is of utmost importance in welding. The process involves high temperatures, bright arcs, and the potential release of hazardous fumes and gases. It is crucial to wear appropriate personal protective equipment (PPE) like welding helmets, gloves, aprons, and safety glasses.

Ventilation in the workspace is also important to prevent the buildup of welding fumes. Additionally, proper grounding and electrical safety measures should be followed.

Prioritizing safety protocols, such as inspecting welding equipment regularly and ensuring the workspace is free from combustible materials, helps minimize risks and creates a safe welding environment.

Welding may seem daunting, but it’s not as hard as it appears. With practice and proper guidance, anyone can learn this skill.

By understanding the different types of welding and safety precautions, you can become a proficient welder. Remember to invest in the right equipment and take your time to develop your technique.

In the end, welding is a valuable skill that opens up various career opportunities and allows you to create amazing things with metal. So don’t be discouraged—give welding a try!