Clamps are these nifty tools that can hold things together like magic. But how do they work? Can you explain how clamps work? Let’s dive in and find out!

Picture this: you’re working on a project and you need to keep two pieces of wood firmly in place. That’s where clamps come to the rescue! These handy devices have jaws that can be tightened to grip onto objects. It’s like giving them a big, reassuring hug!

Clamps use a screw mechanism or a squeeze handle to apply pressure and hold things tightly. Think of it as giving a tight handshake to keep everything in its rightful place.

So, whether you’re a DIY enthusiast or a professional builder, understanding how clamps work is essential for all your fixing and crafting needs. Let’s explore the fascinating world of clamps together!

Demystifying Clamps: How They Work and Why They’re Essential

- Step 1: Choose the right clamp for your needs, considering size, material, and strength.

- Step 2: Position the clamp by aligning the jaws with the material you want to secure.

- Step 3: Adjust the clamp’s tension using the handle or screw mechanism.

- Step 4: Secure the material by tightening the clamp until it holds firmly.

- Step 5: Release the clamp by loosening the tension or removing it completely.

Whether you’re woodworking or working on a DIY project, understanding how clamps work is essential for a secure and stable hold of materials.

1) Understanding the Basics: How Do Clamps Work?

Clamps, at their core, are designed to hold objects firmly together. They achieve this through the application of pressure, effectively immobilizing the objects in place.

The primary component of a clamp is the screw or handle, which allows for tightening or loosening of the clamping mechanism.

The mechanical magic behind clamps lies in their use of leverage. When the handle or screw is turned clockwise, it exerts force on the clamp’s jaws or pads, closing them and applying pressure on the objects being clamped.

The force created by the handle or screw multiplies as it interacts with the moving parts of the clamp, ensuring a secure grip.

The pressure applied by clamps varies depending on their design and purpose. Some clamps exert a light, uniform pressure, perfect for delicate materials like fabric or paper.

Others, such as pipe clamps or vise grips, offer a high degree of force, capable of clamping down on heavy-duty objects. It’s essential to select the right type of clamp for your specific task to ensure optimal results.

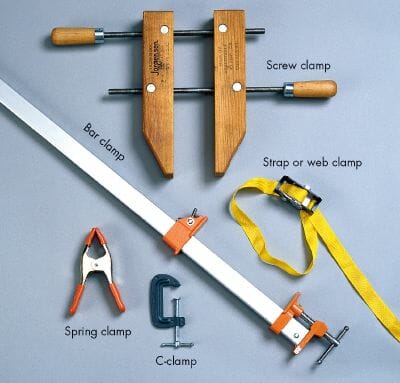

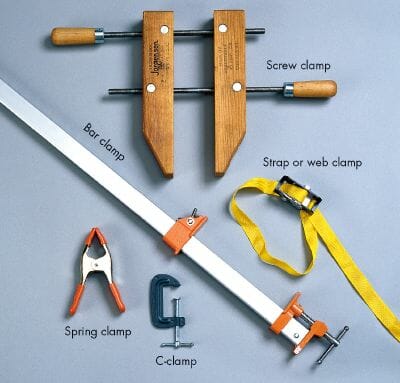

2) Exploring the Different Types of Clamps

Clamps come in a wide array of designs, each tailored to specific applications. Here are some of the most common types of clamps you may encounter:

A) C-Clamps:

C-Clamps, also known as G-Clamps, are a staple in woodworking and metalworking. They feature a C-shaped body with a threaded screw for adjusting the opening width. C-Clamps are versatile, allowing for secure clamping on various materials and shapes.

B) Bar Clamps:

Bar clamps, also referred to as F-clamps, have a similar function to C-clamps but offer a longer reach. These clamps consist of a fixed jaw connected to a sliding bar, allowing them to cover larger surfaces. Bar clamps are commonly used in woodworking projects for holding boards together during gluing or sawing.

C) Spring Clamps:

Spring clamps, as the name suggests, utilize a spring-loaded mechanism for clamping objects. They’re often used for temporary or lightweight applications due to their ease of use and quick-release feature. Spring clamps are commonly found in crafting, photography, and various household tasks.

D) Pipe Clamps:

Pipe clamps, as the name implies, are designed for clamping pipes and cylindrical objects. They consist of a long pipe with a screw and an adjustable jaw attached to it. Pipe clamps are widely used in plumbing and pipefitting work to securely hold pipes during assembly or repair.

E) Quick-Release Clamps:

Quick-release clamps are valued for their fast and efficient operation. They feature a trigger-like mechanism that quickly releases the clamping pressure when needed. Quick-release clamps are popular in woodworking, as they allow for rapid adjustments and repositioning.

F) Vise Grips:

Vise grips, also known as locking pliers, exemplify robust clamping power. These clamps have a pivoting jaw mechanism that automatically locks into place and maintains a firm grip on objects.

Vise grips are especially useful in automotive repairs, providing a secure hold on stubborn or hard-to-reach parts.

3) Practical Applications of Clamps

Now that we have a solid grasp of how clamps work and the different types available, let’s explore their practical applications across various industries:

A) Woodworking:

Clamps are indispensable in woodworking, helping secure boards, frames, and joints during assembly, gluing, or sawing. They ensure precise and accurate alignment, minimizing the risk of errors and improving overall craftsmanship.

B) Metalworking:

In metalworking, clamps assist in holding metal pieces together during welding, drilling, or cutting processes. They maintain stability and prevent movement, resulting in clean and precise metalwork.

C) Construction:

Clamps are essential for reinforcing joints, holding formwork in place, or securing scaffolding for construction projects. They play a vital role in ensuring structural integrity and safety on job sites.

D) Automotive Repairs:

Clamps find extensive use in automotive repairs, helping secure hoses, cables, and various components. They provide a stable grip, enabling mechanics to work efficiently and safely.

E) Arts and Crafts:

From painting and sculpting to textiles and jewelry making, clamps are valuable tools in the art and crafting world. They assist in holding materials together during intricate and delicate processes, enabling artists to bring their visions to life.

F) DIY Projects:

Whether you’re building furniture or assembling shelving units, clamps are invaluable for holding pieces in place. They make DIY projects more manageable, ensuring accurate alignment and reducing frustration.

G) Home Repair and Maintenance:

In everyday life, clamps come in handy for various home repair and maintenance tasks. From fixing loose furniture joints to securing loose cables, clamps provide quick and reliable solutions.

To make the most of clamps, consider the specific needs of your project and select the appropriate type and size accordingly. Remember to follow safety guidelines and always use clamps within their specified limitations.

Choosing the Right Clamp for Your Project

Having discussed the working principles and different types of clamps, let’s dive deeper into choosing the right clamp for your specific project.

Understanding the nuances of various clamp features will help you make informed decisions and optimize your workflow.

4) Factors to Consider When Selecting a Clamp

When choosing a clamp, keep the following factors in mind:

A) Clamping Capacity:

Consider the maximum opening width of the clamp and ensure it fits the thickness of the material you’re working with. Oversized or undersized clamps may compromise the effectiveness and safety of your project.

B) Throat Depth:

Throat depth refers to the distance between the clamp’s jaw and the screw or handle. A deeper throat allows for clamping materials that are farther from the edge.

C) Pressure Distribution:

Different clamps exert pressure differently. Some provide even pressure throughout the clamped area, while others concentrate pressure at specific points. Consider the nature of your project and choose a clamp that distributes pressure appropriately.

D) Specialty Features:

Certain clamps come with additional features to enhance functionality. For example, quick-release mechanisms for rapid adjustments, swivel pads for angled clamping, or soft jaw covers to protect delicate surfaces. Evaluate these added features based on your specific needs.

E) Durability and Materials:

Ensure the clamp is made from durable materials that can withstand the rigors of your project. Look for clamps with sturdy construction and high-quality finishes to ensure longevity.

F) Ease of Use:

Consider the ergonomics of the clamp – the comfort of the handle, the ease of tightening or releasing the mechanism. Clamps with intuitive designs and user-friendly features will make your work more efficient and enjoyable.

G) Budget:

As with any tool, clamps come in various price ranges. Set a budget that suits your project’s needs while considering the quality and durability of the clamp. Remember that a high-quality clamp is a long-term investment that can save you time and frustration in the future.

By taking these factors into account, you’ll be able to choose the right clamp for your project and achieve optimal results.

Tips for Maximizing the Effectiveness of Clamps

Now that you’re well-versed in the world of clamps, here are some additional tips to help you make the most of these versatile tools:

5) Tip 1: Clean and Prep:

Before using clamps, take the time to clean and prepare the surfaces you’ll be clamping. Remove any debris, oils, or adhesives that could hinder the clamping process or affect the final result.

6) Tip 2: Protect Delicate Surfaces:

When working with delicate or finished surfaces, consider using protective pads or jaw covers on your clamps. These accessories prevent scratches, dents, or marks on sensitive materials.

7) Tip 3: Distribute Pressure:

For larger projects or wide surfaces, use multiple clamps to distribute pressure evenly. This ensures a uniform grip and minimizes the risk of warping or distortion.

8) Tip 4: Choose the Right Angle:

In some cases, clamping objects at an angle may provide better stability or access for your project. Experiment with different angles to achieve the best results.

9) Tip 5: Release Tension Gradually:

When removing clamps, release the tension gradually to prevent sudden movements that could damage your project or cause injuries.

10) Tip 6: Explore New Clamps:

Don’t be afraid to experiment with different types of clamps for your projects. Each clamp offers unique features and advantages that can enhance your workflow and expand your creative possibilities.

By following these tips, you’ll elevate your clamping skills and achieve professional-level results.

Clamps are versatile tools that play a crucial role in various industries and projects. Understanding their mechanisms, types, and practical applications allows you to harness their full potential.

By selecting the right clamp for your projects, considering key factors, and implementing useful tips, you’ll be well-equipped to tackle any clamping task that comes your way. Happy clamping!

Frequently Asked Questions

Clamps are tools used to hold objects together or secure them in place. They work by applying pressure, preventing movement or slippage. Here are some common questions about how clamps work:

Q1: How do clamps hold objects together?

Clamps hold objects together by exerting pressure on them. They have two jaws: a fixed jaw and a movable jaw. The fixed jaw remains stationary while the movable jaw can be adjusted to fit the object being clamped. When the movable jaw is tightened, it presses against the object, holding it firmly in place.

Some clamps, like C-clamps or G-clamps, use a screw mechanism to tighten the movable jaw. Others, like spring clamps or quick-release clamps, use a spring mechanism to apply pressure. Regardless of the mechanism used, the purpose of the clamp is to exert sufficient force to prevent movement or separation of the objects being held together.

Q2: What are the different types of clamps?

There are various types of clamps, each designed for specific purposes. Some common types include:

– C-clamps: These have a C-shaped frame and a screw mechanism to tighten the jaws.

– Bar clamps: They consist of a fixed and a sliding bar, allowing for longer clamping capacity.

– Spring clamps: These clamps use a spring mechanism to apply pressure, making them quick and easy to use.

– Pipe clamps: Designed for holding pipes together, these clamps typically have adjustable jaws.

– Toggle clamps: These clamps use a lever system to apply and release pressure, ideal for repetitive tasks.

The choice of clamp depends on the specific application and the amount of pressure required. Different clamps offer different levels of versatility and ease of use.

Q3: How do I choose the right clamp for my project?

Choosing the right clamp for your project depends on several factors:

– The type of material you are working with: Some clamps are better suited for holding wood, while others are designed for metal or plastic.

– The size and shape of the objects you need to clamp: Consider the dimensions and geometry of the objects to ensure the clamp can properly secure them.

– The amount of pressure required: Different clamps offer varying levels of clamping force, so choose one that can provide sufficient pressure for your needs.

– The accessibility of the area to be clamped: If you have limited space or need to reach into tight corners, consider using a clamp with a smaller profile or one with a flexible arm.

By considering these factors, you can select the right clamp that will provide the necessary stability and security for your project.

Q4: Can clamps damage the objects they are holding?

When used properly, clamps should not damage the objects they are holding. However, it is essential to apply the appropriate amount of pressure and use the correct type of clamp for the material and size of the objects.

If too much pressure is applied, it can potentially deform or break the object being clamped. Similarly, using a clamp that is too small or unsuitable for the material can cause damage or inadequate holding power. It is important to choose the right clamp and use it correctly to avoid any potential harm to the objects being clamped.

Q5: What safety precautions should I take when using clamps?

When using clamps, it is important to follow certain safety precautions:

– Use clamps that are in good condition and free from defects.

– Make sure the objects being clamped are stable and properly aligned.

– Avoid over-tightening the clamp, as it can lead to damage or breakage.

– Keep hands and fingers away from the area being clamped to prevent injury.

– When using heavy-duty clamps, use protective gloves and goggles if necessary.

Following these safety measures will help ensure that clamping tasks are carried out safely and effectively without any accidents or damage.

Clamps are handy tools that help hold things together firmly. They have two main parts: the jaw and the screw.

The jaw squeezes the object being clamped, while the screw helps adjust the jaw’s tightness. Different types of clamps are used for different jobs, such as woodworking or metalworking.

Once you understand how clamps work, you can use them to secure objects in place and make your projects easier. They are versatile and useful tools found in many workshops and garages. So, next time you see a clamp, you’ll know exactly how it works!